Over the last decade the McHale range of balers have been operating in over 5 continents in some of the world’s most difficult conditions. McHale balers have developed a reputation for providing high output, excellent reliability, operator comfort and top resale value.

The F5000 range of balers brings baling to a new level with features like progressive greasing and oiling, our drop floor unblocking system which combined with our high specification components, ensures long life, reliability and a machine that is rugged enough to handle the toughest of crops and ground conditions.

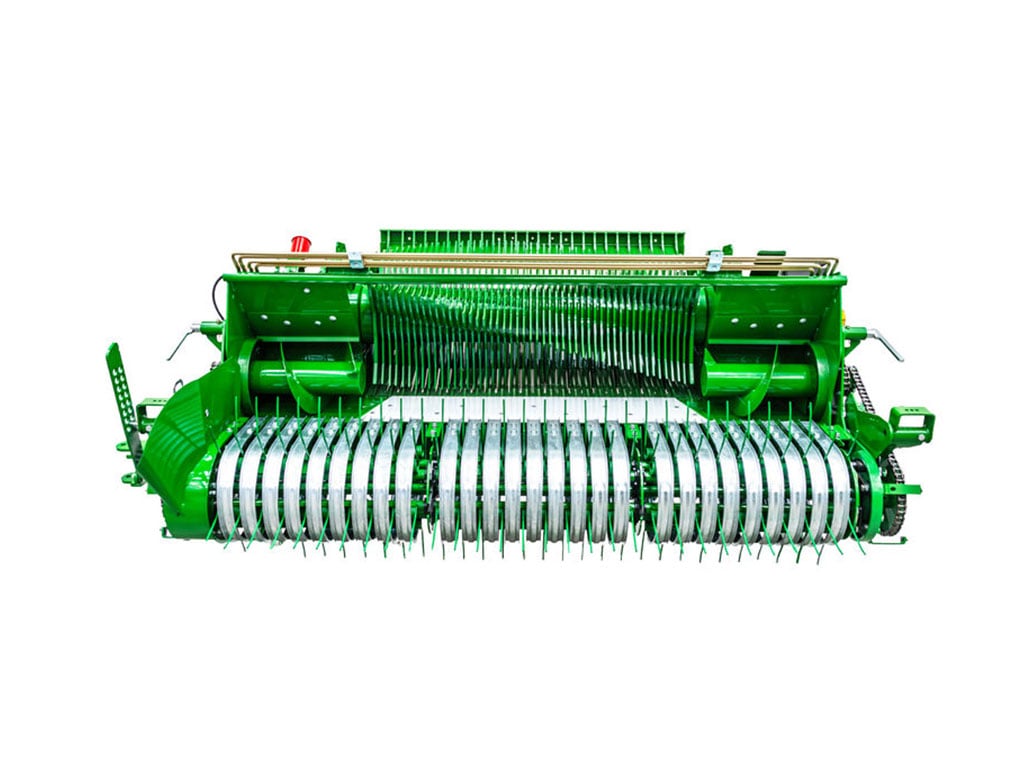

Download Product PDFThe McHale F5600 is a fully automatic Fixed Chamber Baler equipped with load sensing hydraulics and a 25 knife chopper unit. It has the same high capacity chopper unit and rotor as the McHale Fusion 3. Net layers and bale density can be adjusted from the tractor cab using the Expert Plus Control Box, when combined with the load-sensing valve, this makes tailgate opening and closing fully automatic. The machine is fitted with 500/50-22.5 tyres as standard.

| 2.1m Pick-Up | 25 Knife Heavy Duty Feed Rotor | Drop Floor Unblocking System |

| 50 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Automatic Progressive Greasing System |

| Continuous Oiling System | Expert Plus (with Large Graphic Display) |

500/50-22.5 Tyres |

| 18 Roller Bale Chamber | High Performance Vario Stretch Netter | 25 Knife Chopper Unit |

| Knife Pressure Display | Automatic Tailgate Opening & Closing | Load Sensing Valve |

| * 55 mm bearings fitted to rollers with long shafts and double sprockets | ||

Over the last decade, McHale has designed and developed various types of pick-ups. After extensive testing, McHale decided it will offer customers the choice of 2 pick-up options depending on their working conditions:

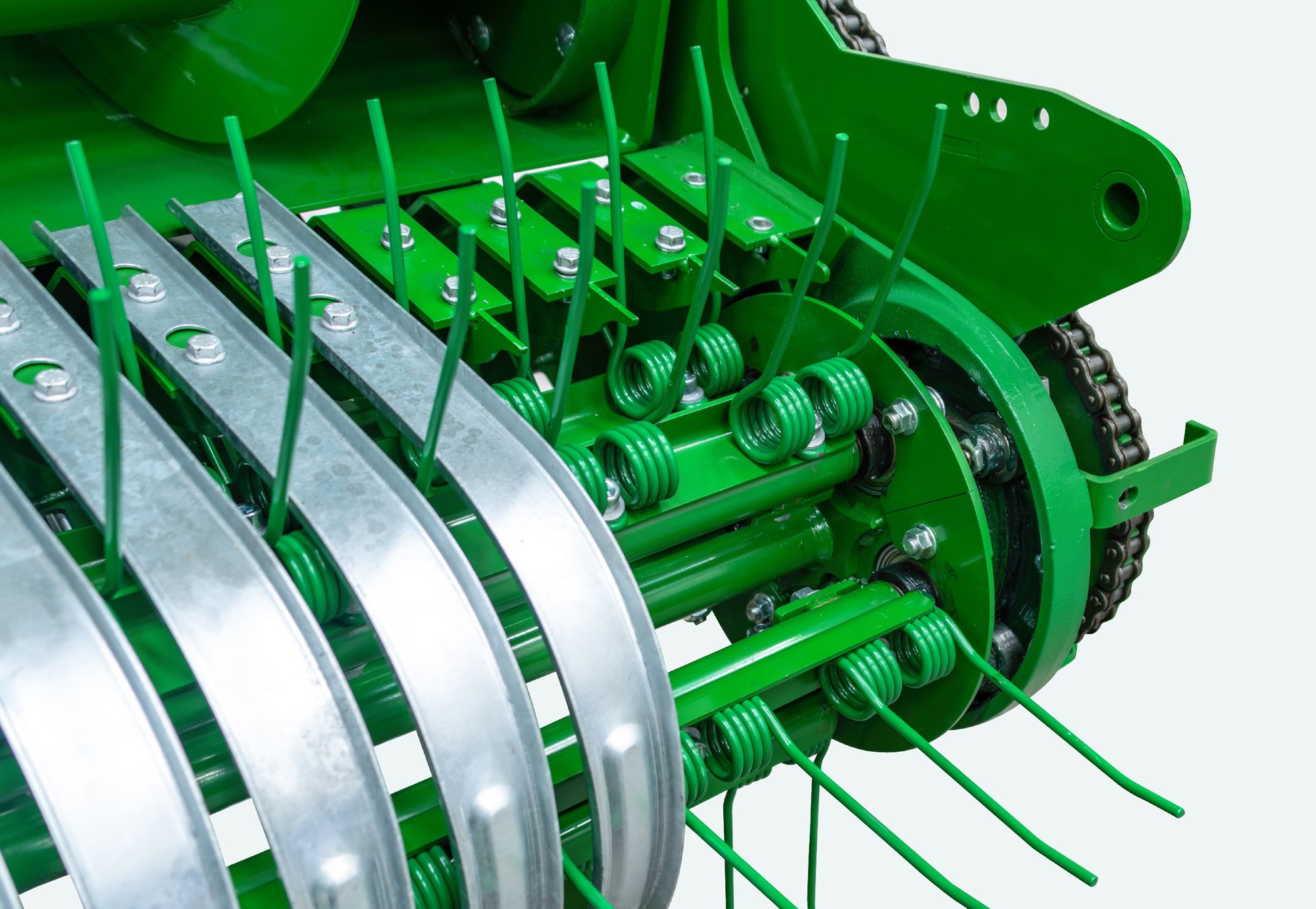

As standard, a cam operated 2.1m high-intake galvanised pick-up ensures excellent ground cleaning in all types of crop. The cam pick-up runs on a cam track that is fitted with double raced cam bearings to stand up to the most testing of conditions.

All cam pick-ups across the McHale Fixed Chamber Baler Range are fitted with 5 tine bars for excellent ground cleaning and delivery of crop to the bale chamber. A side inspection port allows the operator to quickly check and change the cam bearings if needed.

All McHale cam pick-ups have heavy-duty tine bar supports to ensure long service life. McHale have also developed a pick-up tine designed to lift even the shortest of crop

A 2.1m camless pick-up is available as an option on all machines in the McHale Fixed Chamber Baler Range. Six tine bars are fitted to all McHale camless pick-ups to provide excellent ground cleaning and fast delivery of crop to the bale chamber.

The camless pick-up has been designed to increase output, reduce levels of maintenance and perform better in certain conditions.

All camless pick-ups are fitted with a fully welded tine bar. McHale have also developed a pick-up tine designed to lift even the shortest of crop

The specially designed McHale pick-up is positioned close to the rotor to improve delivery of the crop through the rotor to the bale chamber. Large diameter lateral feed augers help direct crop to the bale chamber ensuring a consistent and even crop flow for producing high density bales.

All McHale cam pick-ups have heavy-duty formed tine supports to ensure long service life, while all camless pickups are fitted with a fully welded tine bars. All Profi-Flo camless pick-ups are fitted with two extra columns of tines.

On the Profi-Flo pick-up, the tine bands and feed augers are positioned close to the rotor to improve crop flow from the outside of the wide pick-up. Tapering the augers with 45° ends and removing the steel hydraulic pipes above the pick-up has resulted in a massive reduction in the potential for blockages to occur due to lumps, which ensures a consistent and even crop flow for producing high density bales.

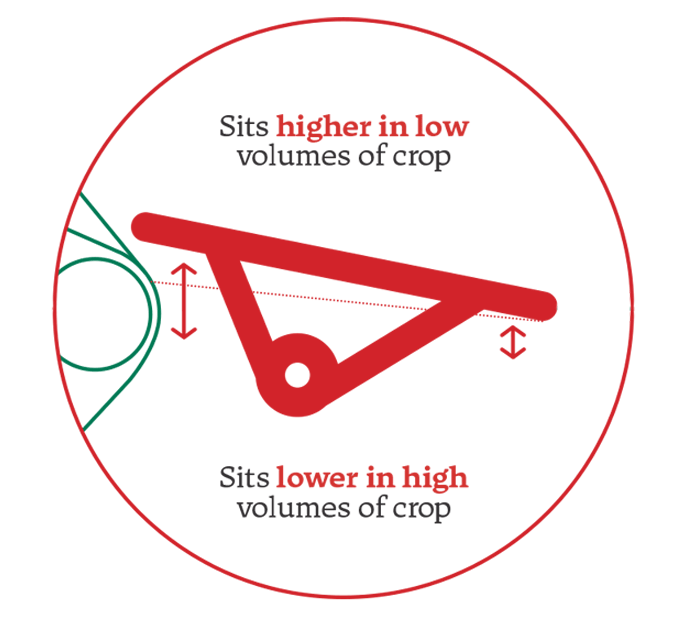

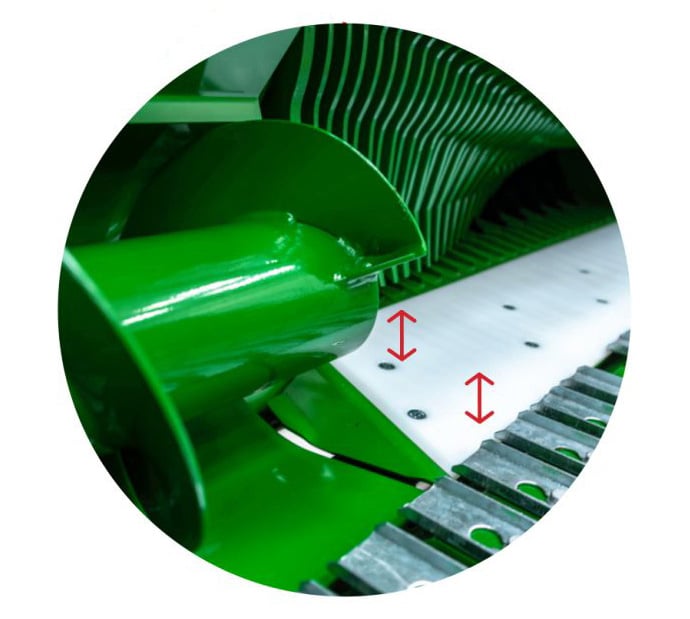

Over the course of a baling season, machines have to work with different volumes of crop. McHale have designed an adaptive intake which allows the intake area to automatically adjust for light and heavy crops to facilitate a smooth crop flow into the chamber.

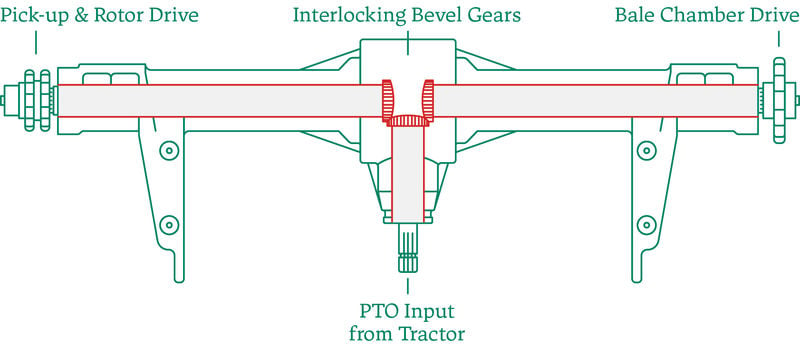

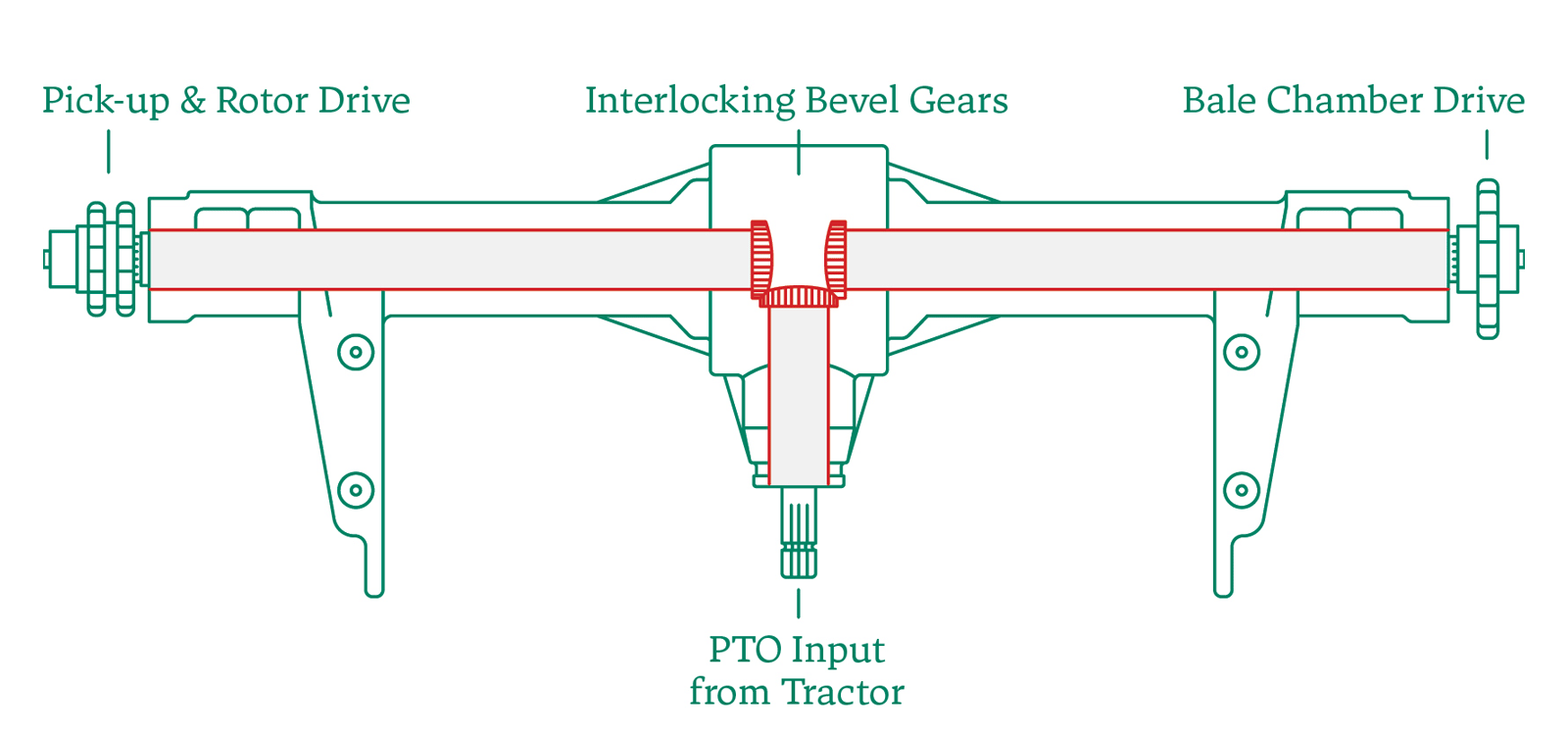

A 540rpm Split Drive Gearbox is fitted to all machines in the McHale Fixed Chamber Range as standard. The gearbox design ensures that power is evenly distributed to both sides of the machine.

The rollers in the bale chamber are driven from the left-hand side of the machine and the pick-up and chopper unit are driven from the right-hand side of the machine. This system ensures direct, short transfer paths, leading to optimal power distribution.

In order to optimise machine performance, a 1000rpm gearbox is available as an optional upgrade on all machines in the McHale fixed chamber baler range.We recommend you speak with your local dealer or distributor regarding which gearbox is best suited to your requirements, based on your working conditions.

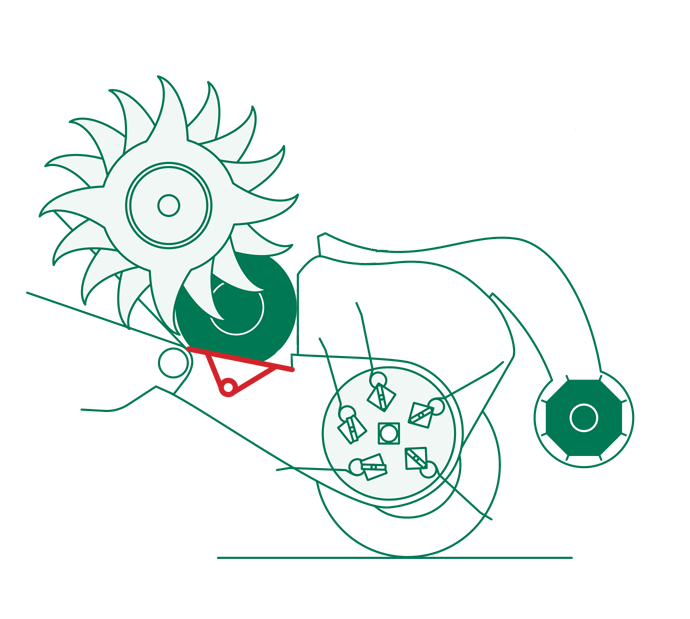

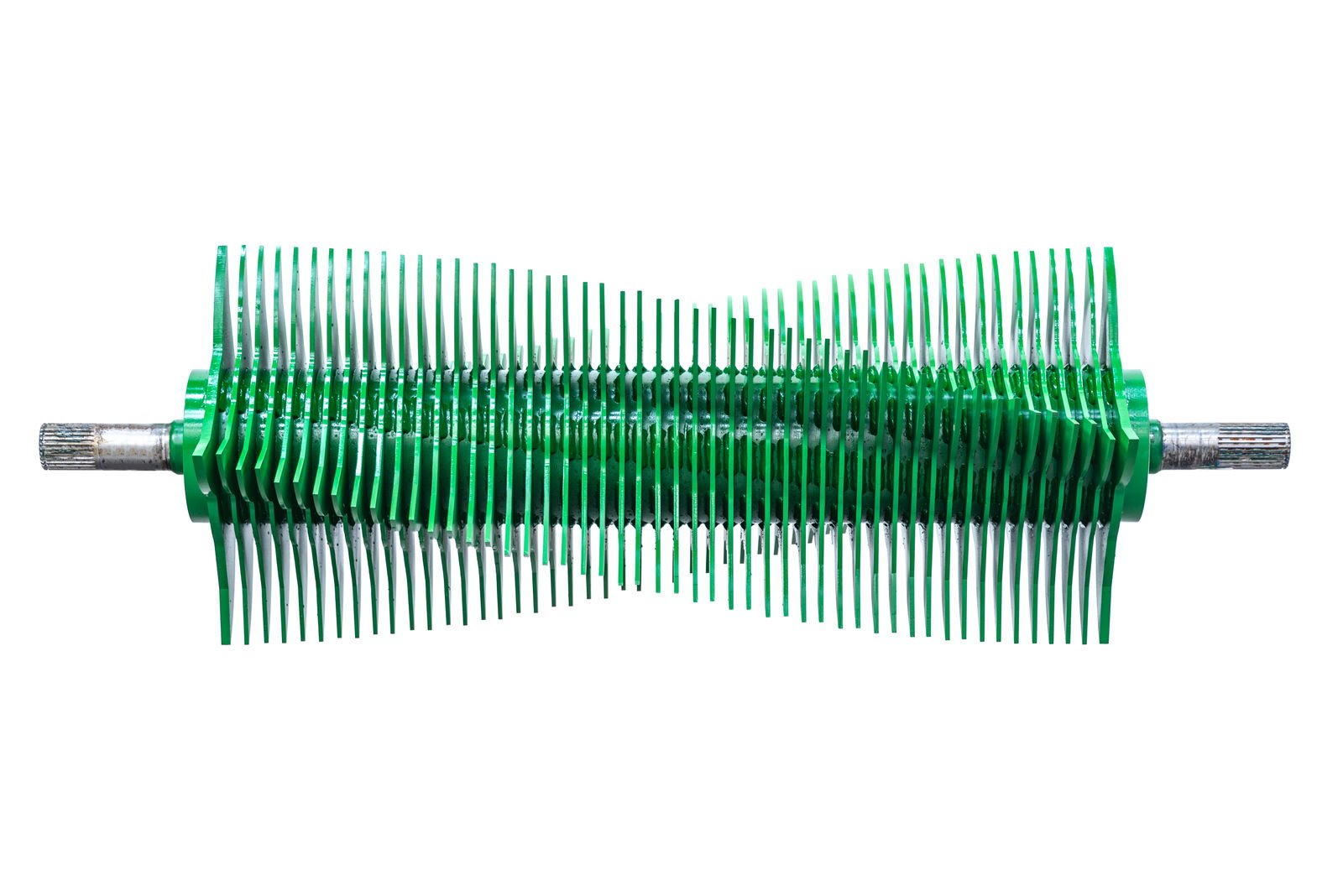

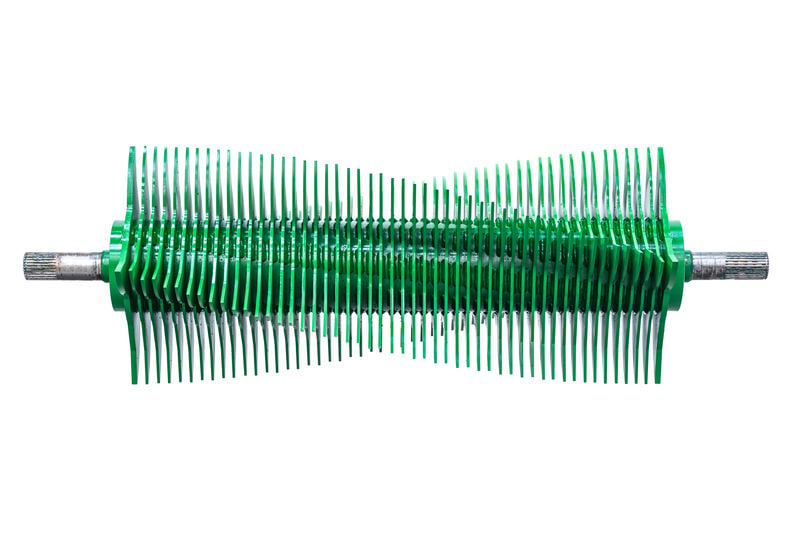

The star shaped, twin finger feed rotor ensures a high-capacity flow of crop into the bale chamber.

The flights on the rotor are laid out in a spiral formation to achieve consistent crop flow. As crop enters the rotor, rotating flights feeds it to the bale chamber. These ensure high output, while the star layout reduces the load peaks as the machines work in heavy swaths.

| Rotor Formation | Spiral |

| Flight Thickness | Inner: 6mm

Outer: 12mm |

| Number of Knives | 25 |

| Selectable Knives | Optional |

To ensure a consistent and even chop quality, a robust and powerful 25 knife chopper unit has been developed for the McHale F5600 fixed chamber baler.

| The 25 knife chopper unit is standard on the McHale F5600. A bank of 25 knives provides a chop length of approximately 46mm. | |

| Flight Thickness | Inner: 6mm

Outer: 12mm |

| Number of Knives | 25 |

| Selectable Knives | Optional |

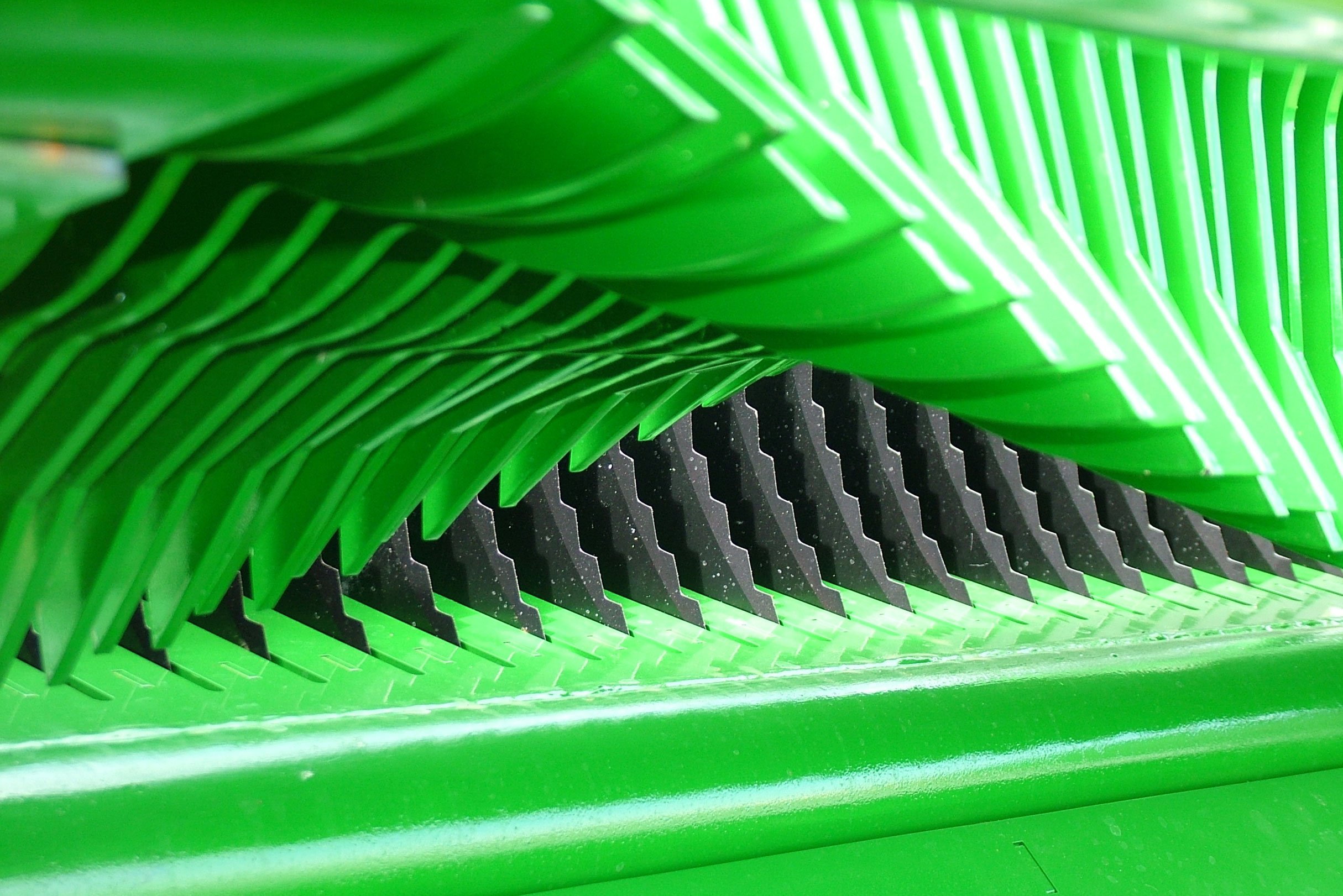

All McHale F5600 machines have the option to be fitted with a selectable knife system. Various knife configurations can be chosen depending on the knife bank specification.

15 Knife Bank Options0, 7, 8, 15 Knifes |

25 Knife Bank Options0, 12, 13, 25 Knifes |

With selectable knives, the operator can vary the chop length by engaging or disengaging either knife bank. If fine chopping is required, the operator can choose to engage both knife banks. Should a longer chop length be required, the operator can disengage one bank of knives from the comfort and safety of the tractor cab.

When using both knife banks separately, if the first bank of knives become blunt, the operator can lower the first knife bank and raise the second bank. This reduces the downtime and allows the operator to continue working. By having consistently sharp knives, fuel consumption is reduced and the machine always delivers optimum chop.

A new sharp set of knives can be engaged, without the operator having to physically replace knives, ensuring a well chopped crop and continued high output. Should different chop lengths be required the operator can make the adjustments by engaging or disengaging the knife bank without having to leave the tractor cab.

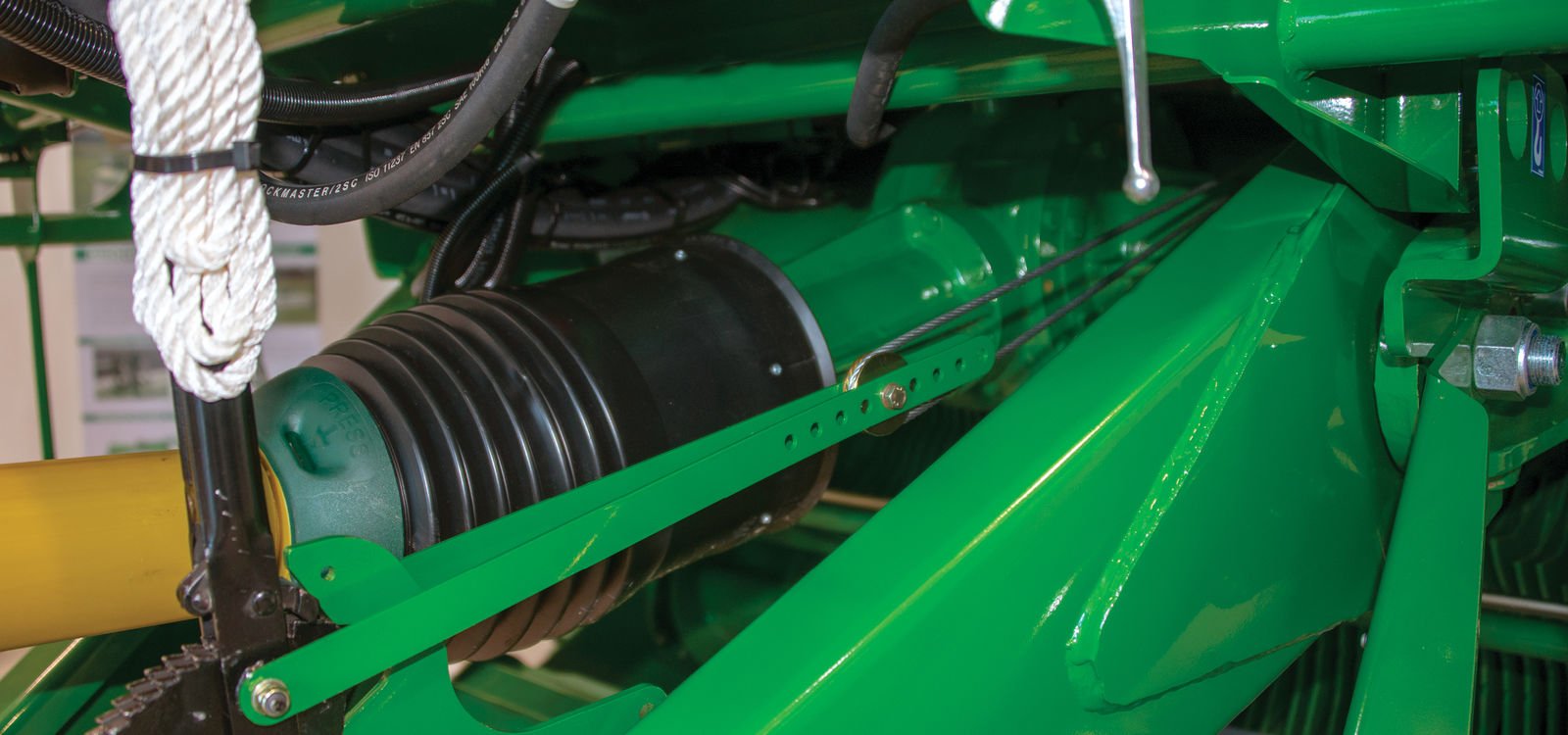

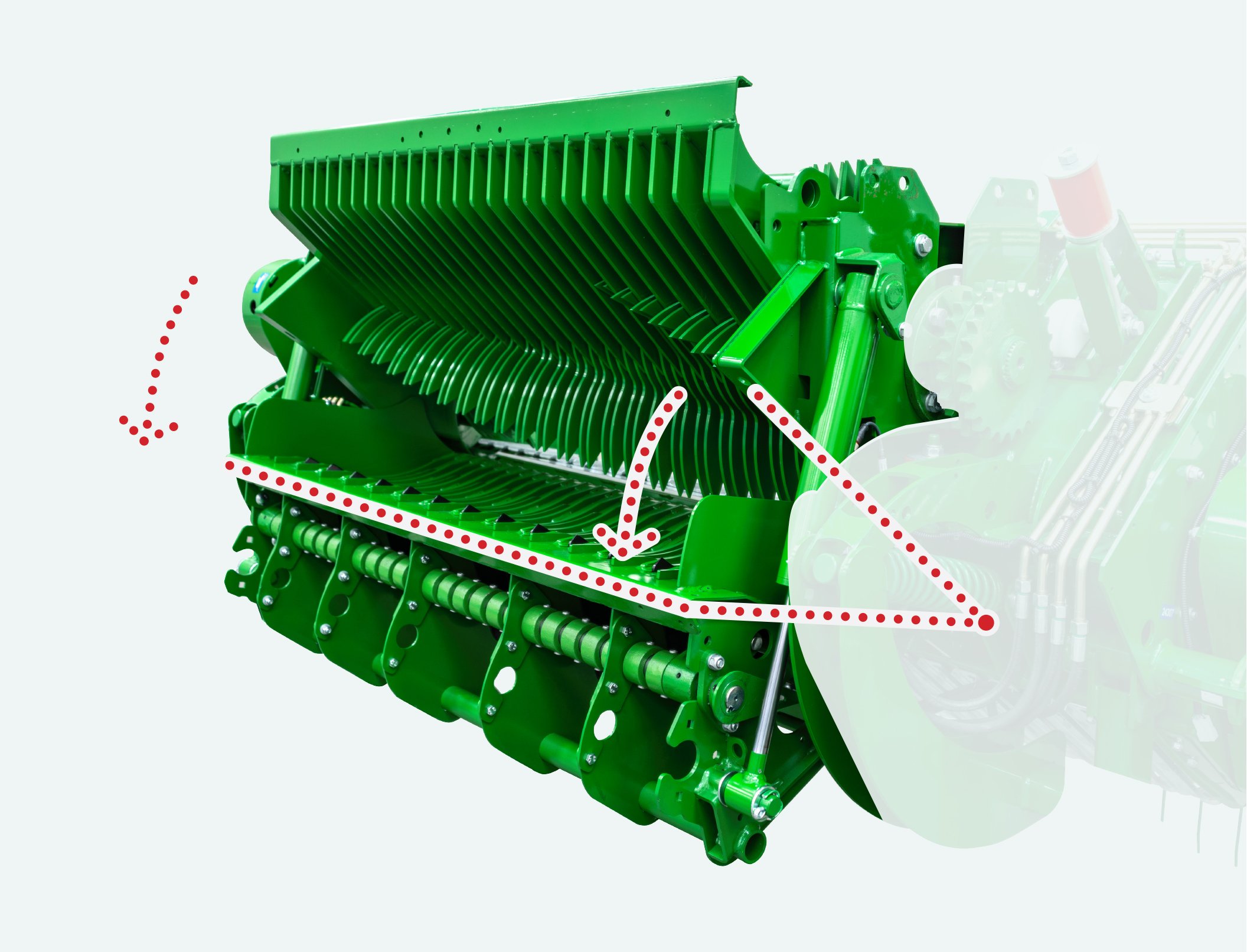

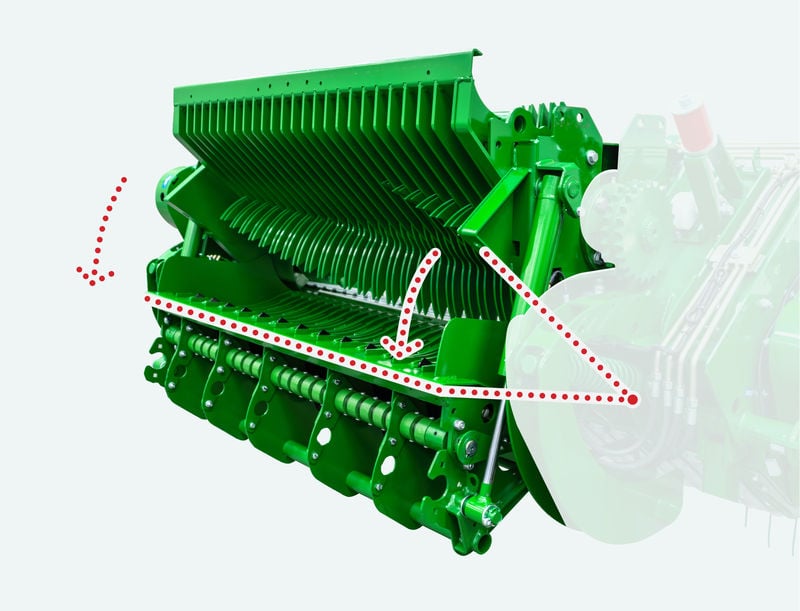

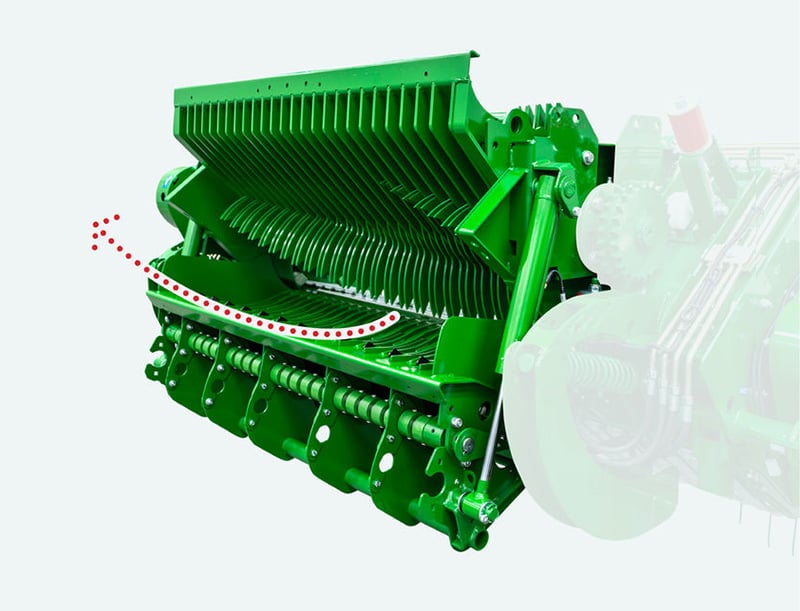

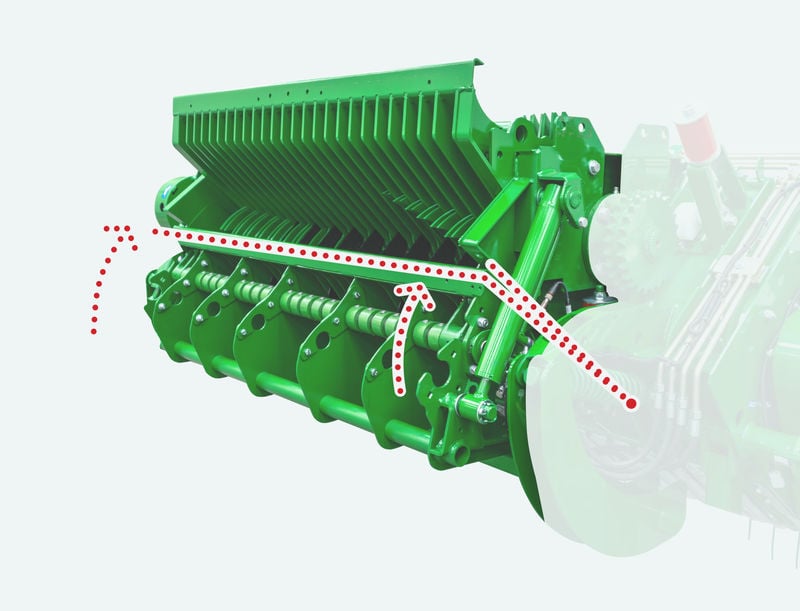

For over a decade, all machines in the fixed chamber baler range are fitted with the McHale Drop Floor Unblocking System, a feature which operators have come to love for it’s simplicity of use and effective unblocking cycle.

Should a blockage occur, the sound of the slip clutch alerts the operator, who can hydraulically lower the floor from the tractor cab. When operating the drop floor cycle, the knives and the drop floor drop together during the unblocking process, giving even more clearance to allow the blockage to be fed through.

This widens the feed channel at both the front and rear of the drop floor where the blockage is more likely to occur. By lowering the front and rear of the drop floor, the blockage can be fed through and effectively cleared when the PTO is re-engaged.

The floor can then be reset to its original position and baling can resume. On the F5500,F5600 and F5600 Plus the drop floor is equipped with a drop floor sensor to ensure the chop quality is consistent by indicating to the operator via the control box if the drop floor is open and the knives are down.

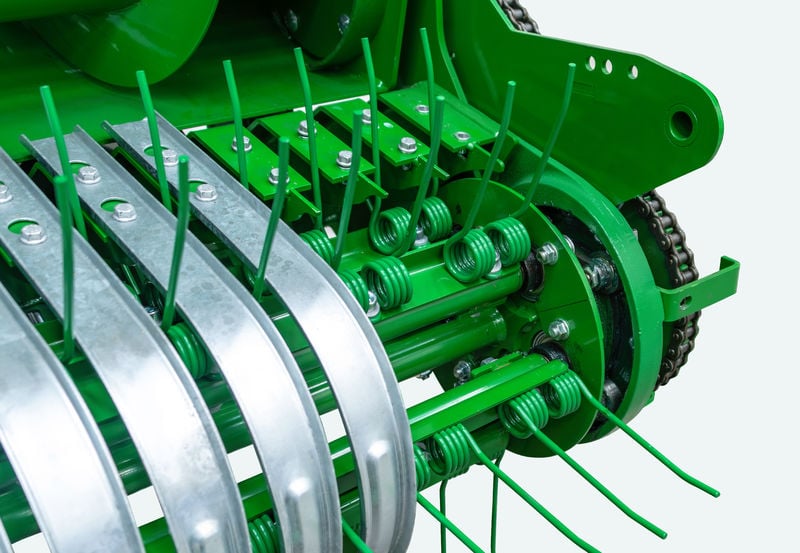

The bale chamber on the McHale F5600 is comprised of an 18 roller bale chamber. It has a diameter of 1.23m x 1.25m (4′ ½” x 4′ 1¼”) and is formed from heavy duty rollers.

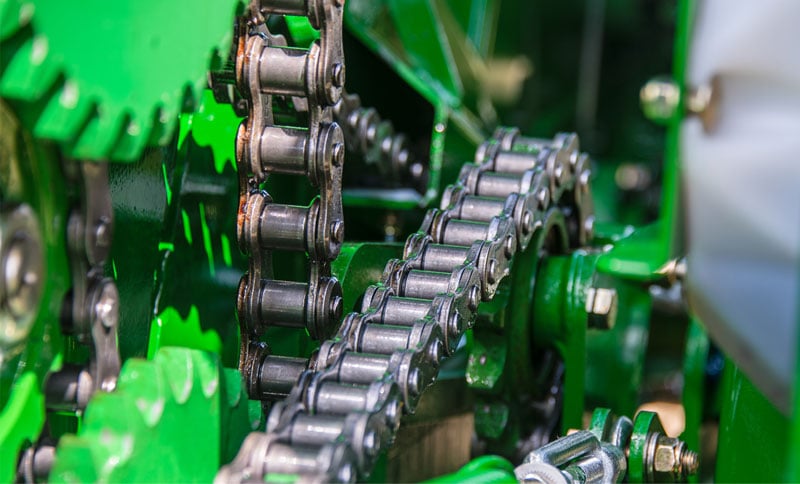

High quality heavy-duty chains ensure reliable operation all around the machine. The main drive chain coming off the gearbox is a high tensile, heavy duty 100H endless chain for maximum strength. All other chains on the drive side of the bale chamber are inch and a quarter (20B). The rotor chain is inch duplex (16 B2) and all pick-up chains are three quarter inch (ASA 60H).

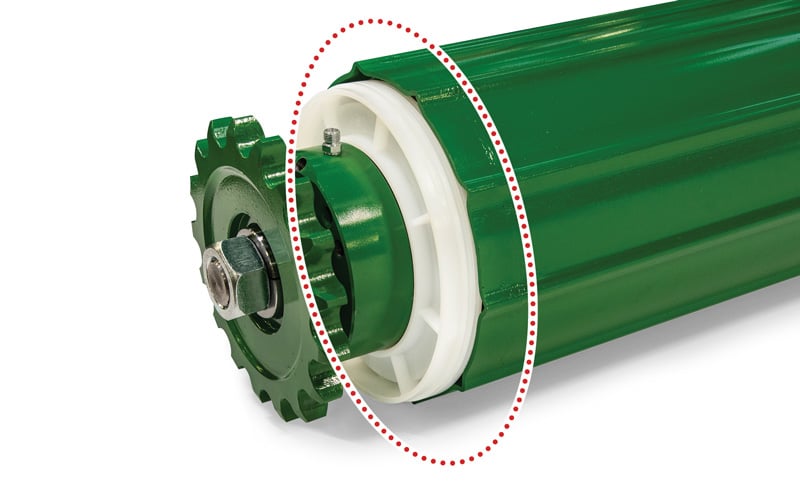

Single sprocket rollers on the chamber drive side are equipped with 50 mm shafts and bearings. Rollers under the most load are fitted with double row bearings. All rollers fitted with double sprockets are equipped with 55 mm shafts and double row 55 mm bearings. The non drive side of the bale chamber is also fitted with heavy duty 50 mm bearings.

On the F5600 and F5600 Plus , bale density can be adjusted from the comfort of the tractor cab via the control box.

Bale chamber rollers are fitted with 50 mm bearings on the drive and non-drive side. Rollers fitted with double sprockets are equipped with 55 mm shafts and double row bearings. All roller ends are fitted with high performance self-cleaning seals that have a unique reverse-thread sealing system that prevents crop from getting into the bearings. The seals prevent the grease around the bearings from becoming contaminated by crop resulting in increased reliability.

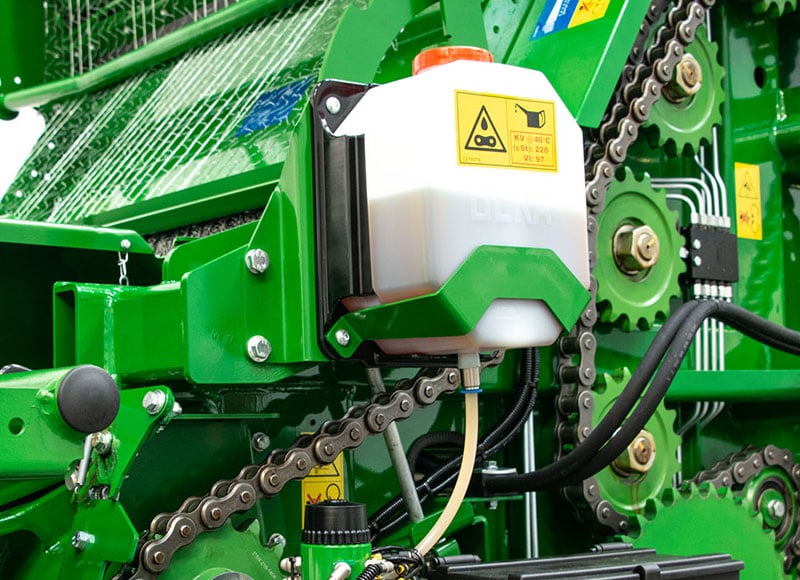

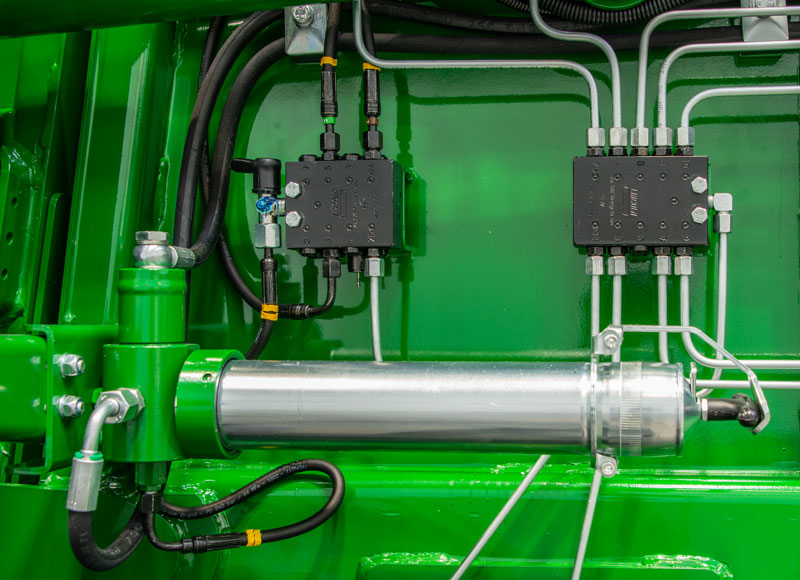

The McHale fixed chamber range of balers are all fitted with a continuous oiling system. Once the PTO is engaged, the continuous oiling system constantly lubricates the chains to ensure a long lifetime. A lube alarm sounds after 300 bales to inform the operator to refill the oil tank.

The continuous oiling system on the machine is driven off the gearbox and delivers oil to the following chains:

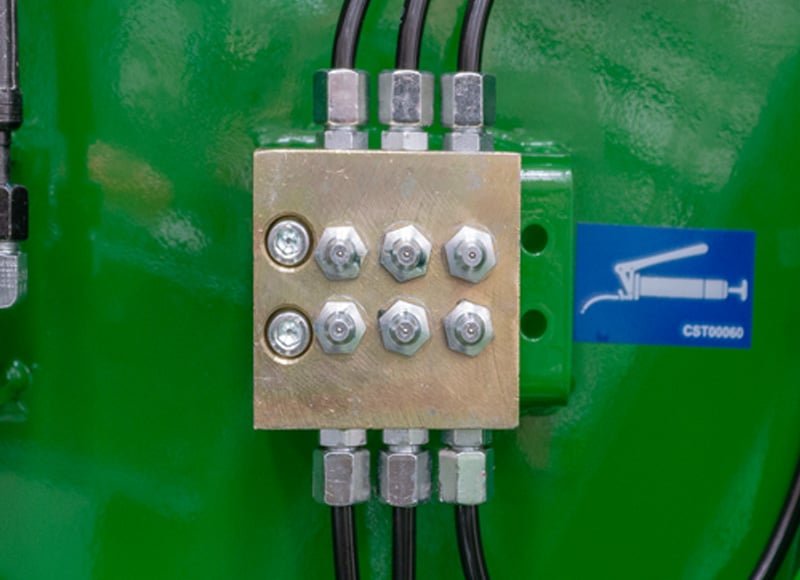

All machines come fitted with a number of manual greasing points which are easily accessible throughout the baler either individually or through a centralised greasing block. The following bearings highlighted below are greased:

With the exception of the McHale F5400, all machines in the McHale Fixed Chamber Baler Range are fitted with automatic greasing as standard. A pressurised system delivers a measured amount of grease every time a bale is ejected from the bale chamber. Automatic greasing saves time as it reduces the amount of manual greasing to be done by the operator. A lube alarm sounds after 300 bales to inform the operator to refill the grease cartridge.

Once the bale is netted in the chamber of the McHale F5600 round baler, the tailgate of the baler automatically opens, allowing the high-density round bale to be ejected.

Once the bale has passed over the bale kicker the tailgate of the baler automatically closes, allowing the operator to continue baling. If the F5600 round baler is operating in hilly conditions the operator can choose to control the bale ejection process with the simple press of a button. On selecting this option the tailgate of the baler will open to release the bale, close and pressurise once the high density round bale has been released.

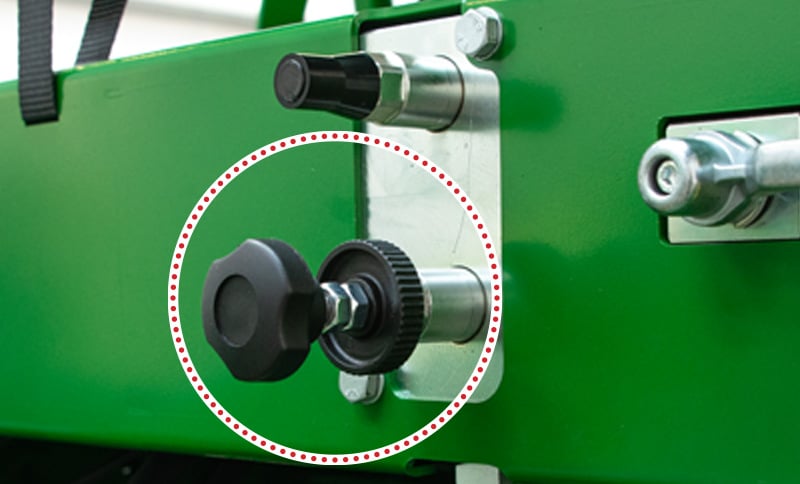

Read lessA high performance netter has been designed and developed for the F5000 range. The net tension can be simply adjusted on a variable pulley on the right hand side of the machine.

This simple, yet effective net binding system applies net to the barrel of the bale ensuring efficient net usage and that a tight layer of net is evenly applied to the bale. The net tension can be adjusted on the machine depending on the operator’s requirements. The number of layers of net being used can be easily adjusted as the machine passes through different crop conditions. On the F5400 and F5500 , by simply moving the net adjustment handle down, more net will be applied, while by moving the handle up, less net can be applied. On the F5600 and F5600 Plus, net adjustment can be controlled from the control box in the tractor cab.

Endless adjustment of tension to ensure optimum bind material usage and bale shape

Capacity to take rolls of net wrap up to 1300 mm in width and 4500m in length.

180-degree wrap around on the rubber feed roller, eliminating any net or film slippage while feeding

Net loading has been optimised on the F5000 baler range by the simple yet very effective rock and roll net loading system.

The operator simply releases the straps on the spare roll of net on the machine platform and rocks the net roll from its storage position over the lip in the platform and rolls it into the net box. Storage for an extra roll of net is provided on the baler platform.

Read lessThe F5600 is equipped with an Expert Plus Control Box, which features a large graphic display; this allows the operator to monitor the baling process graphically from the control console.

The Expert Plus control box features

| Automatic Tailgate Opening and Closing | In-cab Net Adjustment |

| Knife Display | Net Layers |

| In Cab Density Adjustment | Knife Pressure Display |

| Bale Density Setting | Net Usage (Metres) |

| Door Position Display | Drop Floor Control |

| Knife Position Sensor | Lube Count |

| Bale Kicker Sensor | Lube Alarm |

| Pre-Net Bale Formation Alert | Various Bale Counts |

Read less

McHale machines work in different conditions around the world. To optimise machine performance, we offer a number of options in the McHale Fixed Chamber Baler range. We recommend you speak with your local dealer/distributor as regards the best configuration to meet your requirements.

Options F5600

| Camless Pick-Up | Optional |

| Selectable Knives | 0,12,13,25 -Optional |

| 1000rpm Gearbox | Optional |

| Crop Roller | Optional |

| Hydraulic Brakes | Optional |

| Tyre Options | 520/55-22.5 Optional |

Camless Pick-Up

The 2.1m camless pick-up runs smoothly, particularly in short crop, and requires less maintenance due to a reduced number of rotating parts. All camless pick-ups in the McHale fixed chamber baler range are fitted with six tine bars and a double crop roller to provide excellent ground cleaning and fast delivery of crop to the rotor.

Rotor / Chopper Unit

The 25 knife rotor and chopper unit is available as an option on the McHale F5500,F5600 and F5600 Plus fixed chamber machines and delivers a chop length of approximately 46mm.

Selectable Knives

A selectable knife system consists of two knife banks which allow for various knife configurations to be chosen depending on the knife bank specification. If a machine is equipped with 25 knives, then a bank of 12 and a bank of 13 knives are available to be chosen from. Where a machine is equipped with a 15 knife chopping unit, then a bank of 7 and a bank of 8 knives are available to be selected. If no chopping is required then the operator can select for no knives to be engaged. On all F5500 machines, knife selection is engaged from the baler.

1000rpm Gearbox

McHale machines work in different conditions around the world so in order to optimise machine performance, a 1000rpm gearbox is available as an optional upgrade on all machines in the McHale baler range.

Crop Roller

A small diameter high throughput crop roller is available as an optional extra. This crop roller helps to level out uneven swaths and has the ability to increase baler throughput. A Double Crop Roller is also available should it be required.

Brakes

All balers in the McHale F5 fixed chamber baler range can be equipped with brakes as an optional extra. McHale offer the choice of hydraulic or air brakes.

Tyre Options

McHale offer a number of tyre upgrades depending on customer preferences and ground conditions.

Read lessWatch the video for the McHale F5500 15 Knife Chopper Baler which with all 15 knifes engaged, can deliver a theoretical chop length of 65mm. It comes standard with the McHale Drop Floor Unblocking System, Heavy Duty Bearings on the bale chamber, heavy-duty chains and a continuous oiling system.

Tune into the second of our three part series to find out how McHale experts setup and adjust their machines to save money and obtain maximum efficiency and output.

To view the subtitles in your preferred language, please click on the settings icon in the bottom right hand corner of the video and select the required language.

| Width | 2.58 m (8’6″)* |

| Length | 4.05 m (13’3″) |

| Weight | 3700 kg (8,157 lbs) |

| Height | 2.45 m (8′) |

| *Width will depend on tyre selection | |

| Working Width | 2100 mm (6’11”) |

| Pick Up Guide Wheels | Standard |

| Pick Up Lift | Hydraulic |

| Crop Roller | Optional |

| Short Crop Guard | Standard |

| Tine spacing | 70 mm (2 3/4”) |

| Tine Bars | 5 |

| Number of Knives | 25 |

| Theoretical Chop Length | 46 mm (1 3/4”) |

| Knife Protection | Hydraulic |

| Knife Deactivation | Hydraulic from Cab |

| Unblocking System | Drop Floor |

| Width | 1.23 m (4′) |

| Diameter | 1.25 m (4’1”) |

| Greasing | Automatic Progressive |

| Bearings | 50 mm** |

| Number of Rollers | 18 |

| Bale Chamber Feed | Fusion Rotor |

| **Bearings are 55mm double raced on the main load points | |

| Net Adjustment | In Cab |

| Net System | Vario Stretch |

| Net Roll Capacity | 1 + 1 Storage |

| Control | Manual or Automatic |

| Gearbox | Split Drive |

| Main Drive Protection | Cam Clutch |

| Pick Up Protection | Slip Clutch |

| Chain Lubrication | Continuous |

| Control System | Expert Plus Control Console |

| Operation | Automatic |

| Density Adjustment | In Cab |

| Axle | 8 Stud |

| Tyres Standard | 500/50 – 22.5 |

| Bale Kicker Indicator | Standard |

| Road Lights | Standard |

| Minimum Power Requirement | 75 kW (100hp) |

| Hydraulics | 2 Double Acting Spools |