The McHale Variable Chamber Baler Range is made up of V6, V8 and Fusion Vario machines. The range consists of 7 models;

• V6740 – Non-Chopper Baler

• V6750 – 15 knife Chopper Baler

• V6760 – Fully Automatic Chopper Baler

• V8940 – High-Capacity Non-Chopper Baler

• V8950 – High-Capacity Chopper Baler

• V8960 – Fully Automatic High-Capacity Chopper Baler

• Fusion Vario Plus– Integrated Baler Wrapper with Film on Film Technology

Offering innovative ideas to allow you to work smarter, whilst achieving more output, the McHale name has become synonymous with the production of robust and reliable machines, making McHale the number one choice for professional users.

Download Product PDFThe McHale V8950 is a high capacity, semi-automatic variable chamber baler which is fitted with a 15-knife chopper unit and heavy-duty rotor. It is capable of producing bales from 0.6–1.9m (2’–6’3″).

A double drive system aids belt rotation and bale formation to allow the machine to operate in the toughest of conditions. The machine comes with centralised grease blocks as standard. Automatic greasing is available as an optional extra. Net and bale density can be adjusted from the cab through the Expert Plus control console.

The machine is fitted with 500/50-22.5 tyres as standard.

| 2.1m Pick-Up | 15 Knife Chopper Feed Rotor | Drop Floor Unblocking System |

| 50 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Centralised Greasing Blocks (Manual Greasing) |

| Continuous Oiling System | Expert Plus Control Console | 500/50/22.5 Tyres |

| High Performance Netter | Bale Kicker | Mechanical Tailgate Locking |

| 3-Endless Belts | Drop Floor Sensor | |

| * 55 mm bearings fitted to rollers with long shafts and double sprockets | ||

Over the last decade, McHale has designed and developed various types of pick-ups. After extensive testing, McHale decided it will offer customers the choice of 2 pick-up options depending on their working conditions:

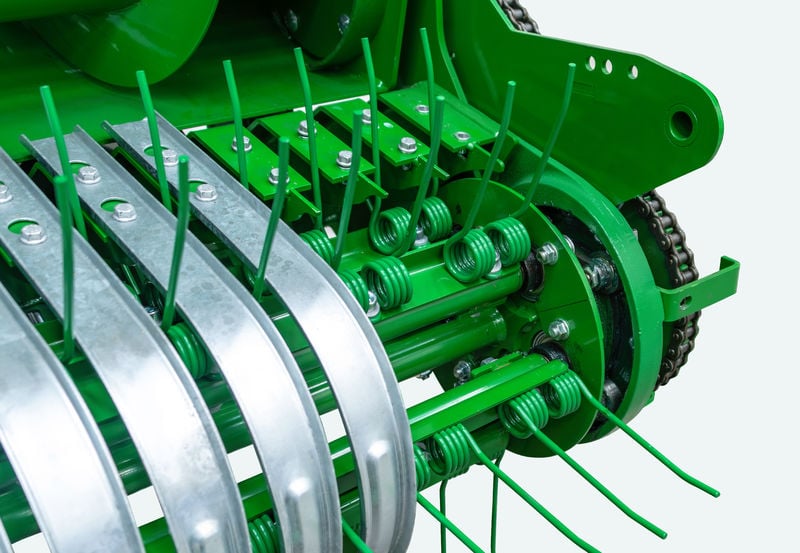

As standard, a cam operated 2.1m high-intake galvanised pick-up ensures excellent ground cleaning in all types of crop. The cam pick-up runs on a cam track that is fitted with double raced cam bearings to stand up to the most testing of conditions.

All cam pick-ups across the McHale Variable Chamber Range are fitted with 5 tine bars for excellent ground cleaning and delivery of crop to the bale chamber. A side inspection port allows the operator to quickly check and change the cam bearings if needed.

All McHale cam pick-ups have heavy-duty tine bar supports to ensure long service life. McHale have also developed a pick-up tine designed to lift even the shortest of crop

A 2.1m camless pick-up is available as an option on all machines in the McHale Variable Chamber Range. Six tine bars are fitted to all McHale camless pick-ups to provide excellent ground cleaning and fast delivery of crop to the bale chamber.

The camless pick-up has been designed to increase output, reduce levels of maintenance and perform better in certain conditions.

All camless pick-ups are fitted with a fully welded tine bar. McHale have also developed a pick-up tine designed to lift even the shortest of crop

The specially designed McHale pick-up is positioned close to the rotor to improve delivery of the crop through the rotor to the bale chamber. Large diameter lateral feed augers help direct crop to the bale chamber ensuring a consistent and even crop flow for producing high density bales.

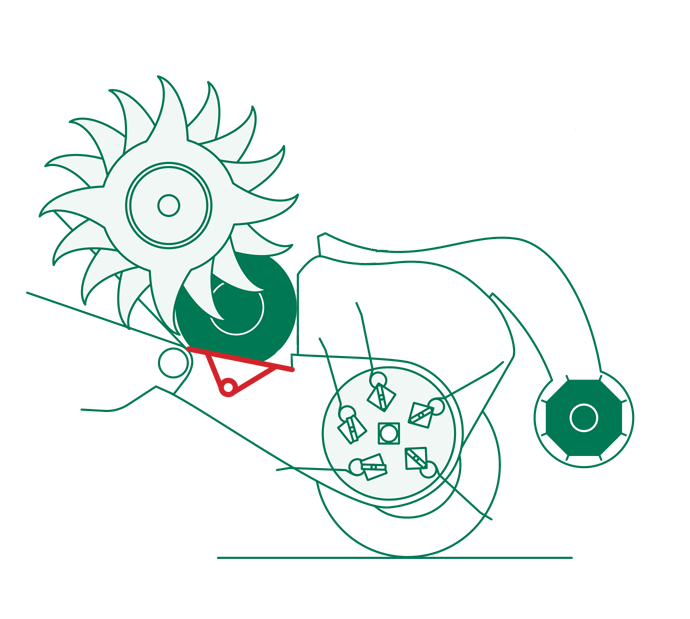

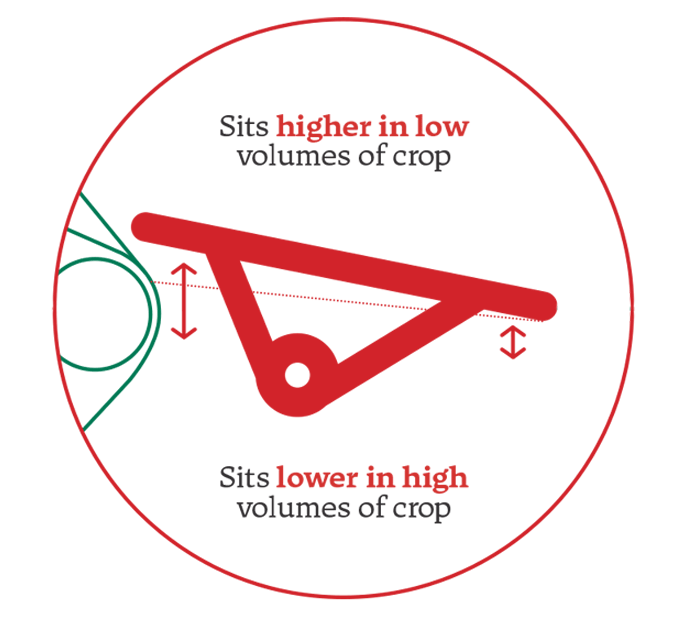

Over the course of a baling season, machines have to work with different volumes of crop. McHale have designed an adaptive intake which allows the intake area to automatically adjust for light and heavy crops to facilitate a smooth crop flow into the chamber.

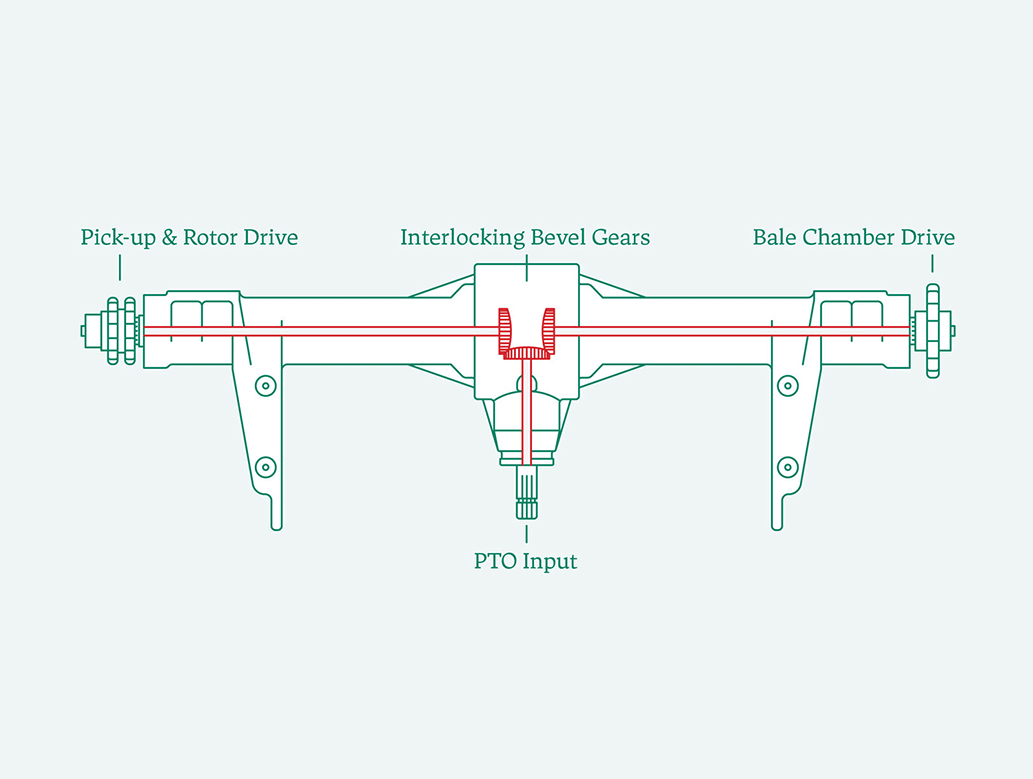

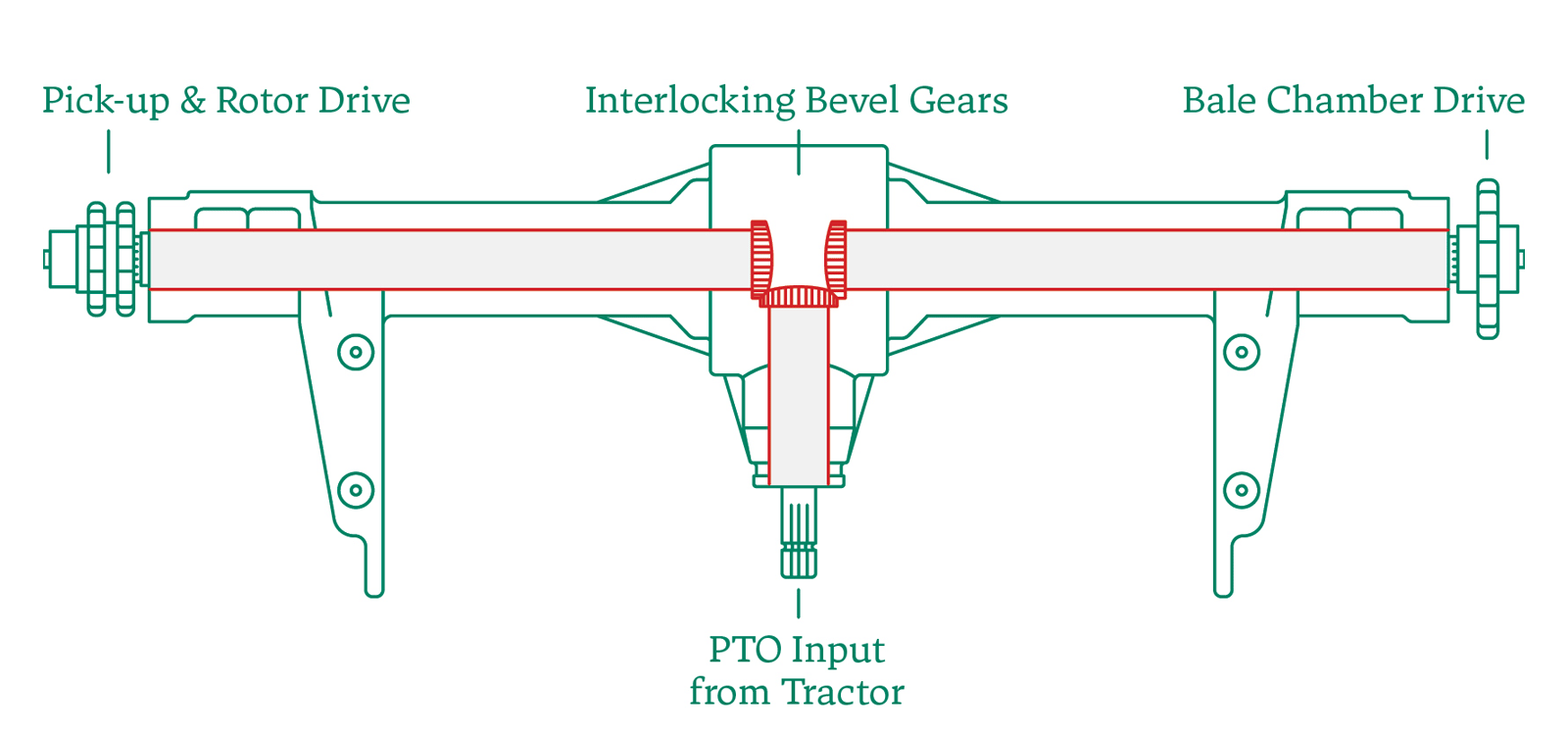

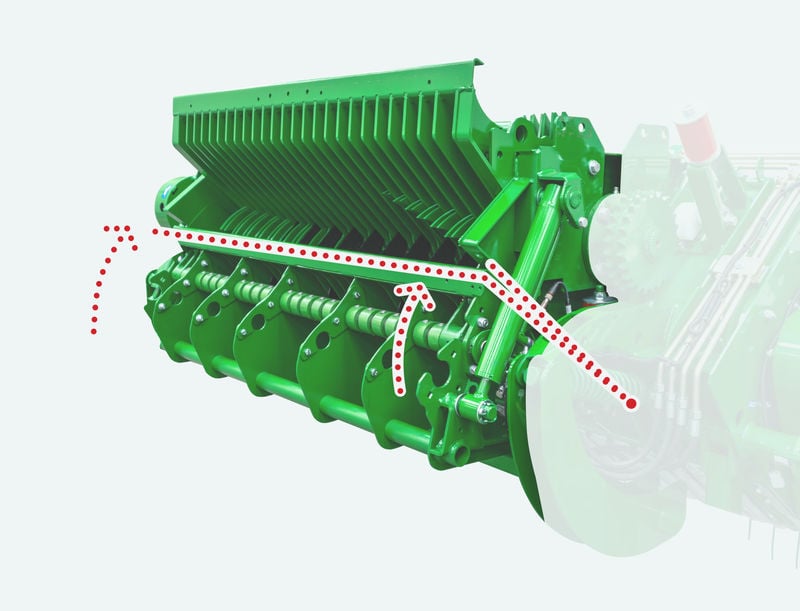

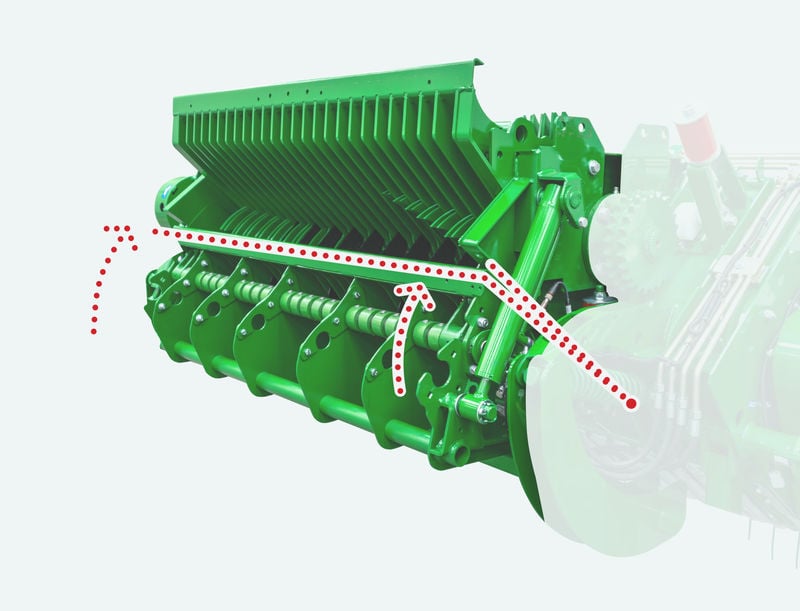

A 540 rpm Split Drive Gearbox is fitted to all machines in the McHale Variable Chamber Baler Range as standard. The gearbox design ensures that power is evenly distributed to both sides of the machine.

The rollers in the bale chamber are driven from the left-hand side of the machine and the pick-up and chopper unit are driven from the right-hand side of the machine. This system ensures direct, short transfer paths, leading to optimal power distribution.

In order to optimise machine performance, a 1000rpm gearbox is available as an optional upgrade on all machines in the McHale variable chamber baler range.In order to optimise machine performance, a 1000rpm gearbox is available as an optional upgrade on all machines in the McHale variable chamber baler range.

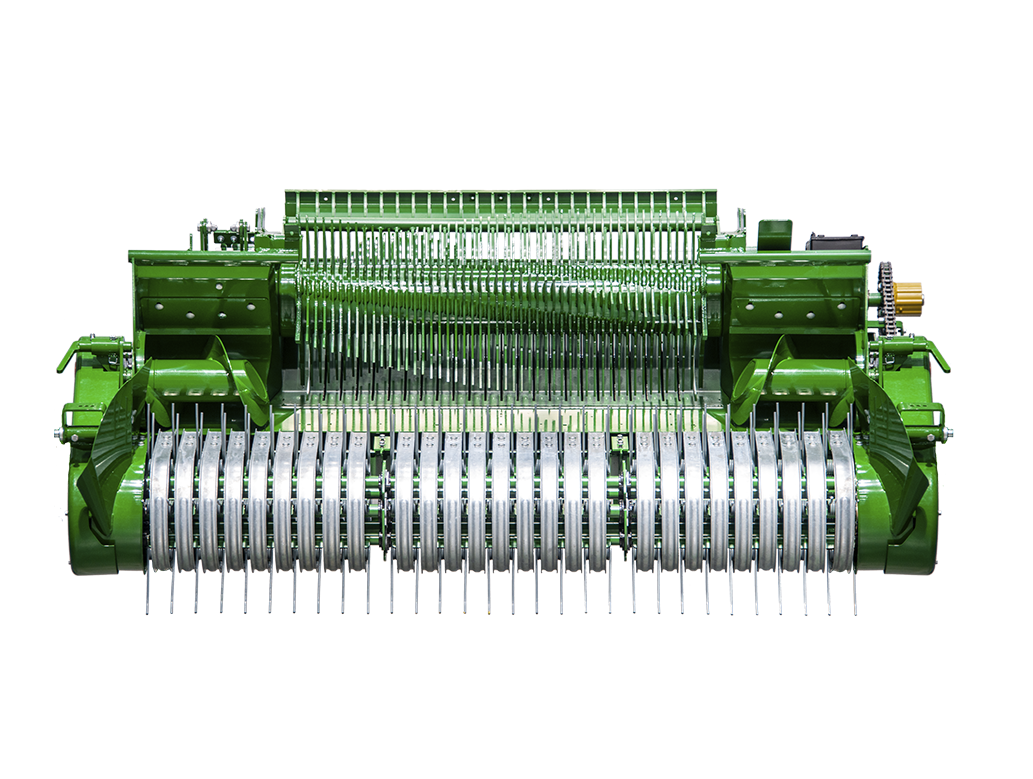

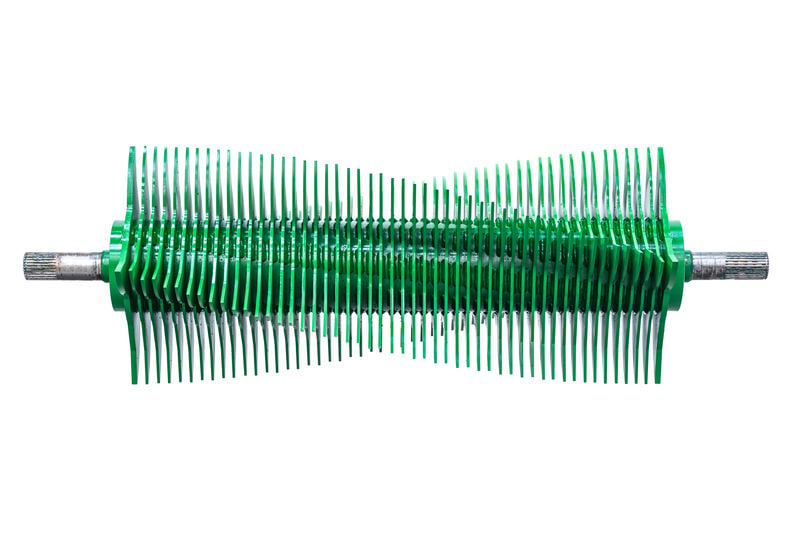

The star shaped feed rotor ensures a high-capacity flow of crop into the bale chamber. McHale have designed 3 rotors for the Variable Chamber Baler Range.

The flights on the rotor are laid out in a spiral formation to achieve consistent crop flow. As crop enters the rotor, rotating flights feeds it to the bale chamber. These ensure high output, while the star layout reduces the load peaks as the machines work in heavy swaths.

| Rotor Formation | Spiral |

| Flight Thickness | Inner: 8mm

Outer: 12mm |

| Number of Knives | 15 |

| Selectable Knives | Optional |

| Rotor Formation | Spiral |

| Flight Thickness | Inner: 6mm

Outer: 12mm |

| Number of Knives | 25 |

| Selectable Knives | Optional |

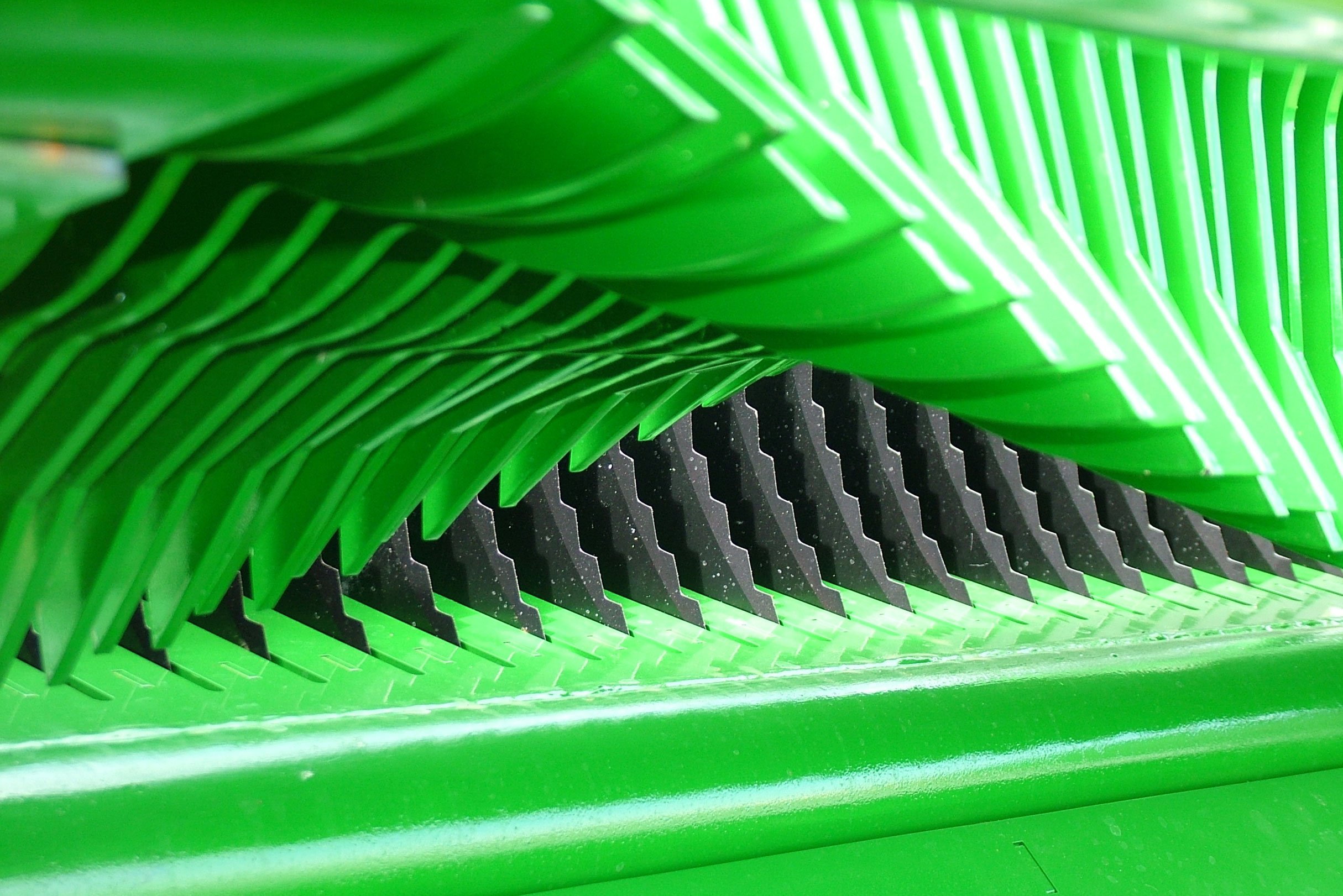

To ensure a consistent and even chop quality, two chopping options have been developed for the McHale variable chamber machines.

| The 15 knife chopper unit is the standard chopper unit on the McHale V8950. A bank of 15 knives provides a chop length of approximately 65mm. | |

| Flight Thickness | Inner: 8mm

Outer: 12mm |

| Number of Knives | 15 |

| Selectable Knives | Optional |

| The 25 knife chopper unit is available as an option on the McHale V8950. A bank of 25 knives provides a chop length of approximately 46mm. | |

| Flight Thickness | Inner: 6mm

Outer: 12mm |

| Number of Knives | 25 |

| Selectable Knives | Optional |

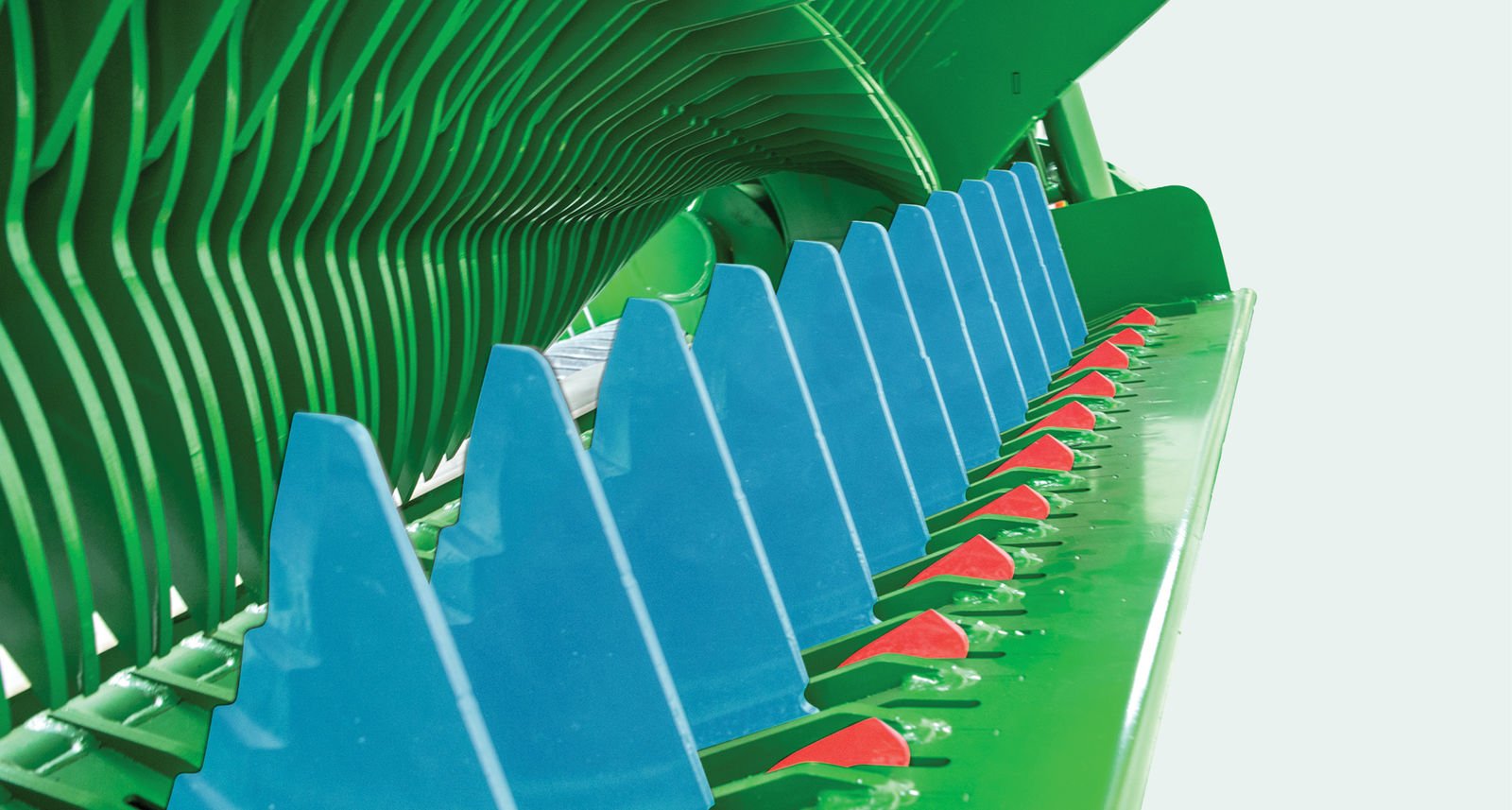

All McHale V8950 machines have the option to be fitted with a selectable knife system. Various knife configurations can be chosen depending on the knife bank specification.

25 Knife Bank Options0, 12, 13, 25 Knifes |

With selectable knives, the operator can vary their chop length by engaging or disengaging either knife bank. If fine chopping is required, the operator can

choose to engage both knife banks. A reduction in chop length can also be quickly and easily achieved without the operator having to remove knives.

When the operator is using only one knife bank, this can easily be swapped to the second knife bank from the cab to provide a fresh set of sharp knives. By having consistently sharp knives, fuel consumption is reduced as less power is required to chop the crop with sharp knives.

Without the operator having to physically replace knives, a new sharp set of knives can be engaged, ensuring a well chopped crop and continued high output. Should different chop lengths be required the operator can make the adjustments without having to alter the knives.

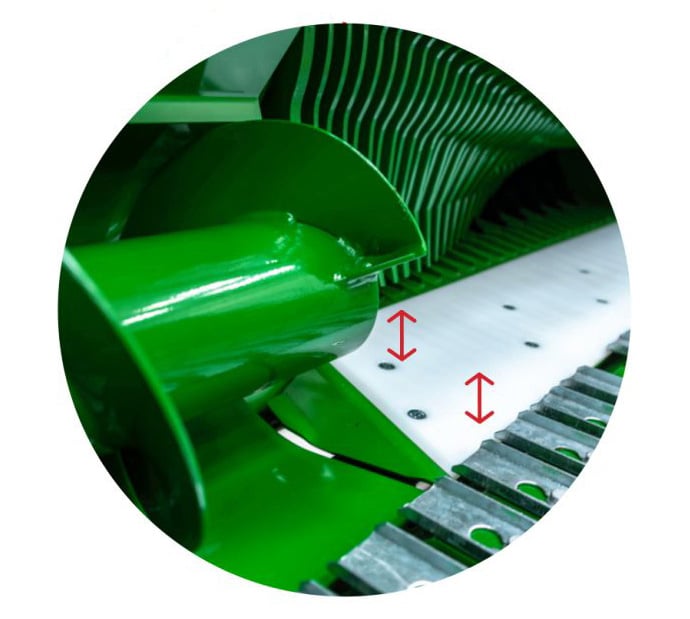

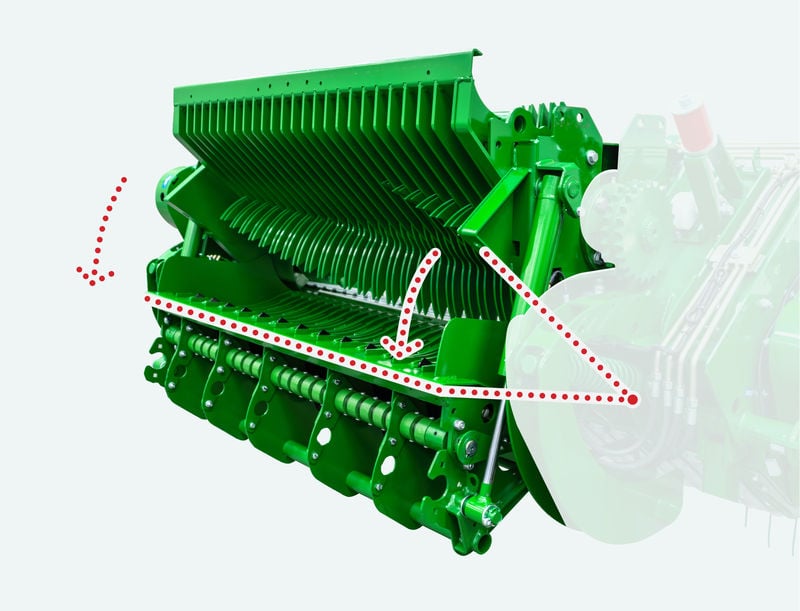

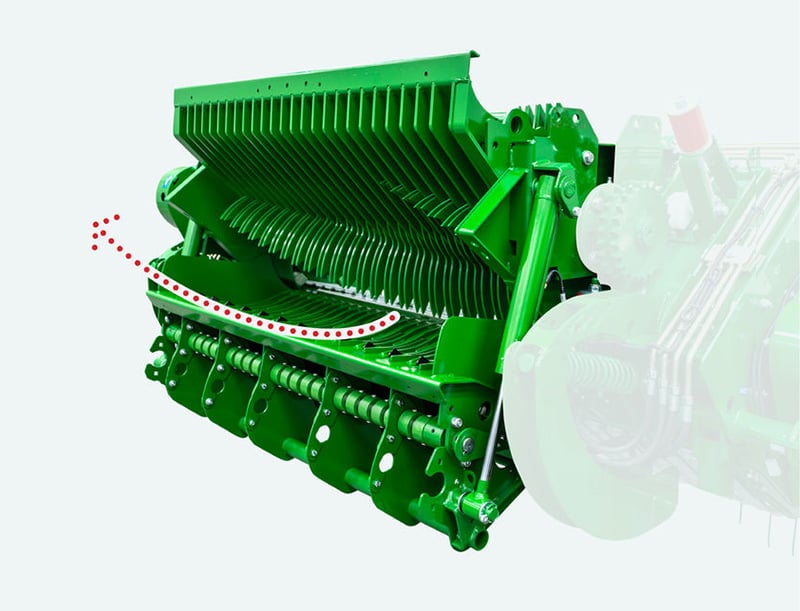

For over a decade, all machines in the Variable Chamber Baler Range are fitted with the McHale Drop floor unblocking system, a feature which operators have come to love for it’s simplicity of use and effective unblocking cycle.

Should a blockage occur, the sound of the slip clutch alerts the operator, who can hydraulically lower the floor from the tractor cab. When operating the drop floor cycle, the knives and the drop floor drop together during the unblocking process, giving even more clearance to allow the blockage to be fed through.

This widens the feed channel at both the front and rear of the drop floor where the blockage is more likely to occur. By lowering the front and rear of the drop floor, the blockage can be fed through and effectively cleared when the PTO is re-engaged.

The floor can then be reset to its original position and baling can resume. The drop floor is equipped with a drop floor sensor to ensure the chop quality is consistent by indicating to the operator via the control box if the drop floor is open and the knives are down.

The bale chamber on the McHale variable chamber baler range is comprised of heavy-duty endless belt(s). The belts are extremely hard wearing and are reinforced with synthetic material, which ensures that the belt(s) can absorb and apply high pressure to the material in the Bale chamber.

Bale SizesThe V8940 can make a bale from 0.6m (2 ‘) to 1.9m (6 ‘3 “) |

Size IncrementsThe bale size can be adjusted up from the minimum setting in increments of 10mm (2/5″) |

Three Endless BeltsAll V6/ V8 variable chamber balers are equipped with 3 heavy duty endless belts as standard. These strong belts exert high pressure in order to form a dense bale in the chamber and are manufactured to the highest of standards using layers of synthetic and rubber material to form a durable endless belt with no joins. |

Single Belt (Optional)A single full width endless belt is also available as an optional extra on the V6740 and V6750. This full width belt reduces crop loss, particularly in alfalfa and provides better belt traction for the operator compared to multiple endless belts. |

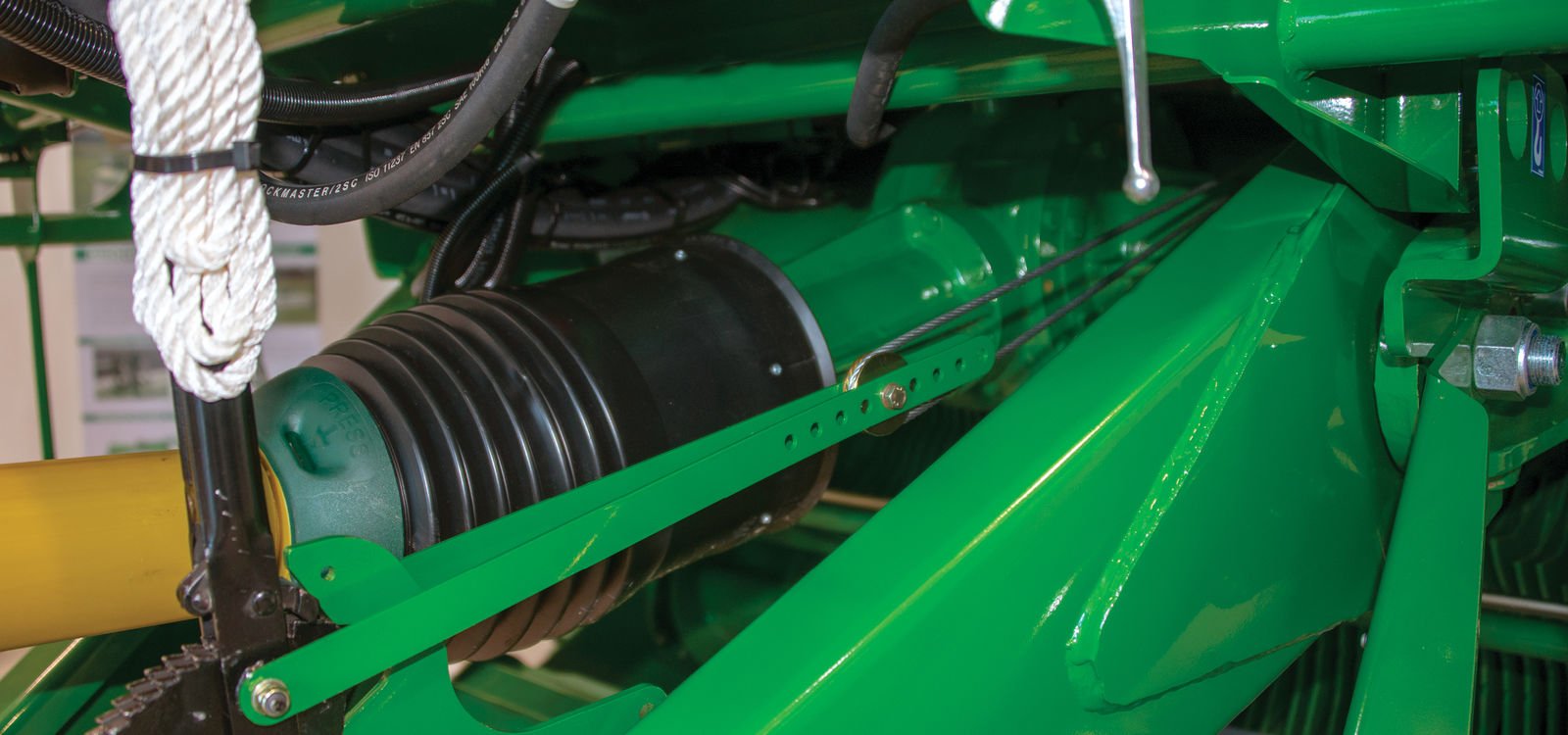

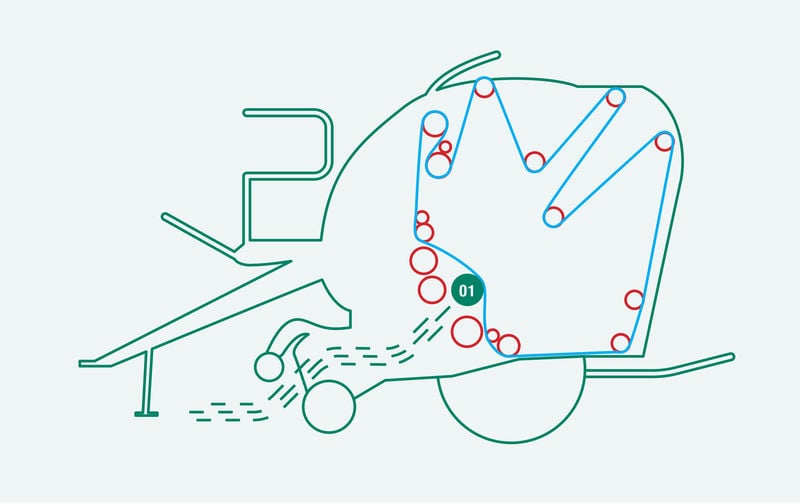

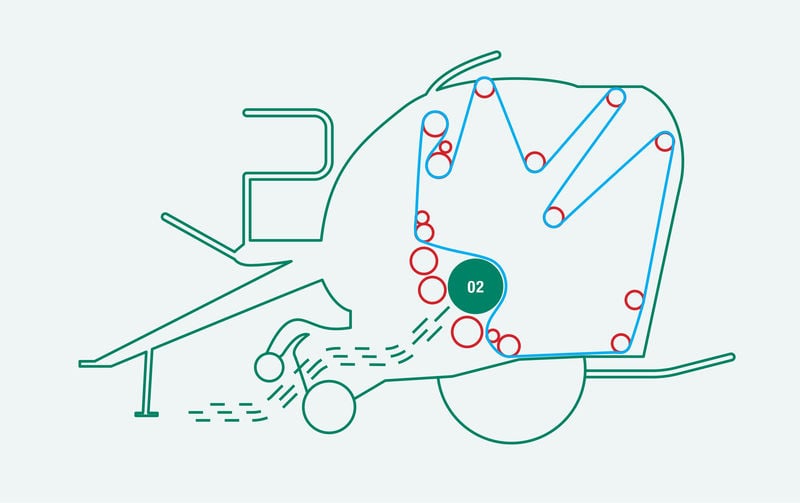

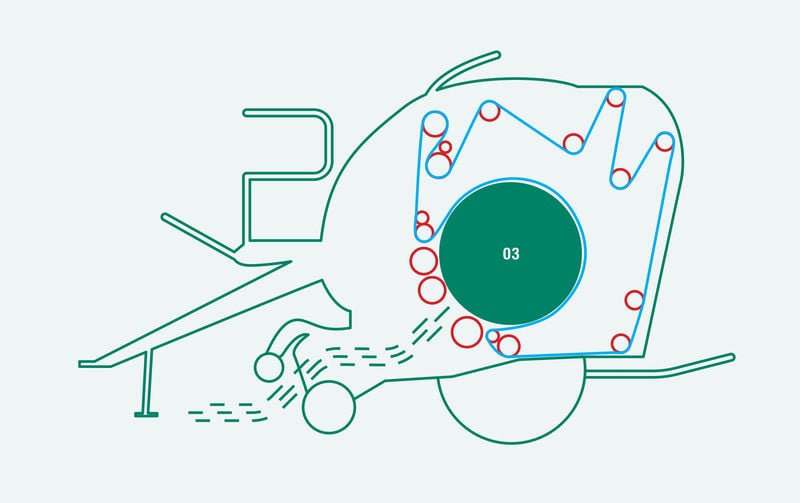

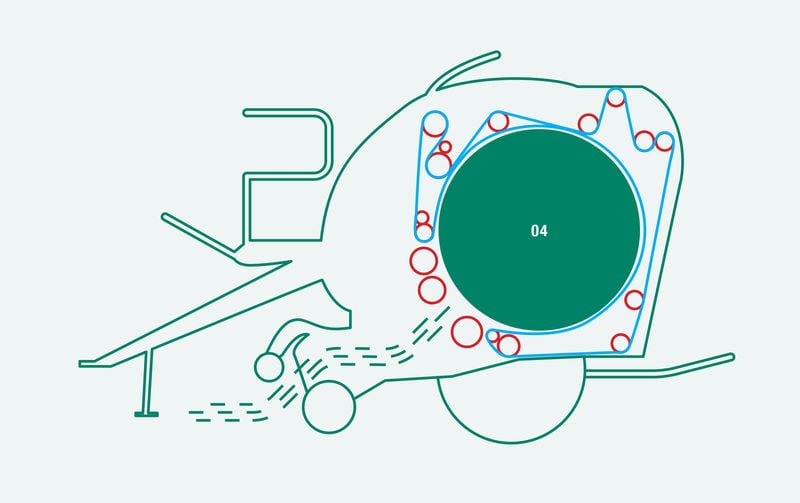

McHale have developed a bale chamber that can quickly form the bale from the start. The operator can commence baling at full speed as the progressive density system can quickly adjust to ensure that pressure is exerted on the crop right from the core of the bale, regardless of bale size.

This is done by four heavy-duty springs that pressurise the crop at the start of the baling process. The tension placed on the crop by these large springs allows for the perfect start to the bale. The spring tension on the belts ensures easy bale formation and a properly formed core.

As the bale is forming inside the chamber, the hydraulics take over the tensioning of the belt(s) from the four large springs. Two hydraulic rams control the tension on the chamber belt(s) as the bale forms inside the chamber.

Just like the core of the bale, the outer layers are compressed at the same consistent pressure using both springs and hydraulics until the set bale density and size is reached.

A heavy-duty drive system powers belt and bale rotation on all machines in the variable chamber baler range. On the McHale V8950, a double drive system is fitted to ensure belt rotation and bale formation.

In more difficult conditions, such as wet heavy grass, if the primary drive slips slightly, the double drive will engage in order to aid belt and material rotation in the chamber. This double drive helps bale formation as a constant pressure is kept on the chamber belts which results in the production of a solid and uniform bale even when dealing with a wet and heavy crop.

A cleaning auger is fitted to the double drive system in order to prevent crop build up and allow the double drive to aid bale rotation when working in wet or sugary crops.

Ultra-sonic bale shape indicators are fitted to all McHale Variable Chamber Balers and indicate to the operator via the control console which side of the chamber needs to be filled.

The tailgates on all McHale variable chamber balers are fitted with a pair of mechanical locks, which keep the bale chamber securely closed. These locks remain activated until, the progressive density system reaches the preset bale size and density and the required amount of net has been applied. This eliminates the need for the chamber door to rely on hydraulic pressure when making high density bales.

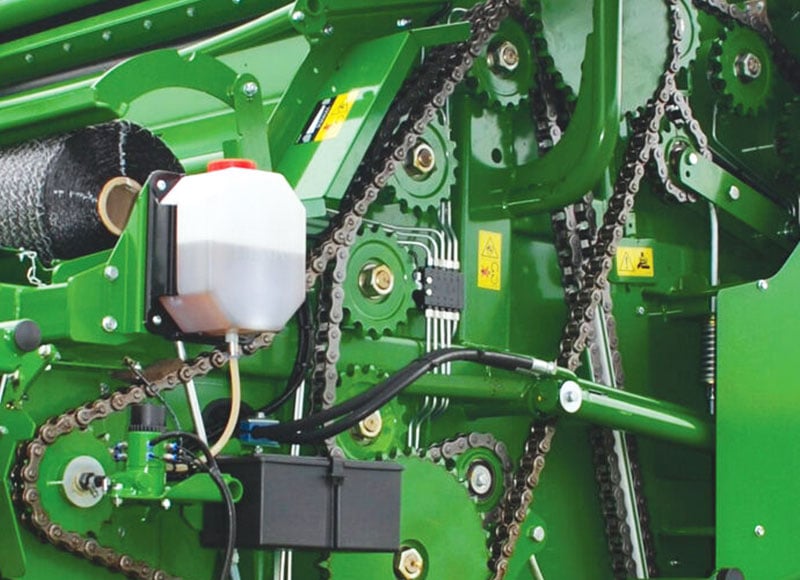

The McHale variable chamber baler range of balers are all fitted with a continuous oiling system. Once the PTO is engaged, the continuous oiling system constantly lubricates the chains to ensure a long lifetime. A lube alarm sounds after 300 bales to inform the operator to refill the oil tank.

The continuous oiling system on the machine is driven off the gearbox and delivers oil to the following chains:

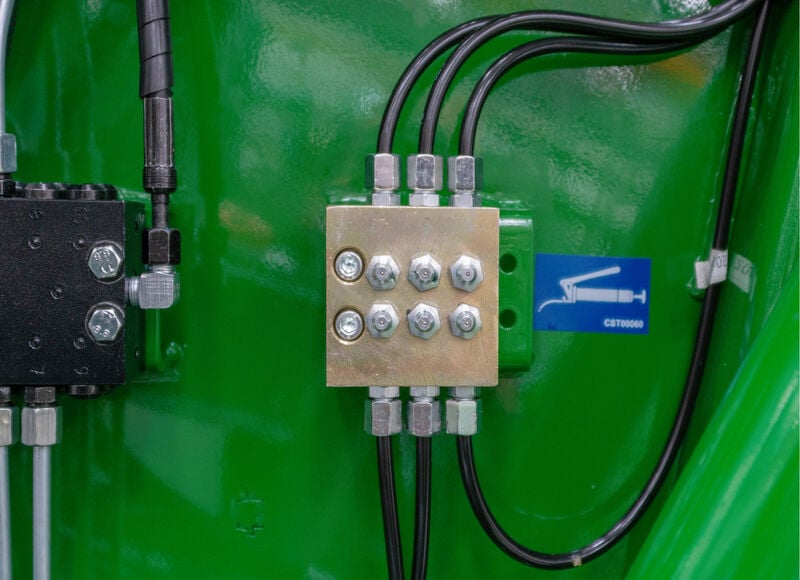

All machines come fitted with a number of manual greasing points which are easily accessible throughout the baler either individually or through a centralised greasing block. The following bearings highlighted below are greased:

Automatic greasing is available as an option on all McHale V6750 and V8950 machine. A pressurised system delivers a measured amount of grease around the baler every time a bale is ejected from the bale chamber. Automatic greasing saves time as it reduces the amount of manual greasing to be done by the operator. The grease cartridge should be refilled after 1200 bales

A high performance netter has been designed and developed for the McHale variable chamber baler range. This netter is very reliable and and comprises of a moving roller which allows the roll of net to rotate as it is being applied to ensure even net application.

A simple yet very effective netting system comprising of a moving roller allows the roll of net to rotate as it is being applied to ensure even net application. Net is stretched around the bale using a hydraulic brake. The brake places a resistance on the speed at which the roll of net can rotate, the greater the resistance the more stretch that is applied to the net. The operator can adjust net tension without having to leave the comfort and safety of the tractor cab.

McHale V6 & V8 balers are fitted with a bale discharge sensor, which notifies the driver when the bale has left the bale chamber and has passed over the heavy-duty bale kicker ensuring a clean separation between the machine and the netted high-density bale. Storage for two extra rolls of net is also provided on the baler platform.

Endless adjustment of tension to ensure optimum bind material usage and bale shape

Capacity to take rolls of net wrap up to 1300 mm in width and 4500m in length.

180-degree wrap around on the rubber feed roller, eliminating any net or film slippage while feeding

The McHale V8950 is fitted with an Expert Plus control console, which has a large graphic display.

|

|

|

|

|

|

The Expert Plus console, also gives the operator the choice of selecting a soft or hard bale core, depending on the customers feed out requirements. The control console can also store ten bale count totals so the operator can record ten different counts that may be associated with different fields or different customers

The bale diameter can be adjusted on the control console from 0.6–1.9m (2’–6’3″) on the V8950. The preset diameter setting is displayed on the bottom information block on the main screen and a live diameter reading is displayed as the bale is being formed. There is also a vertical bar graph which shows progress as the bale is being made.

A bale profile setting retains the operators personal setting choice from core diameter, bale diameter, core density, bale density, net layers and net stretch for use in different crops. There are 5 bale profile settings to choose from. Each profile will retain its own individual settings so that the machine can easily be changed to work in different crops without needing to change a lot of settings.

The variable chamber baler range is fitted with bale shape indicators, which indicate to the driver via the control box, which side of the chamber needs to be filled, ensuring that when the machine works in a light swath that the best bale shape is achieved. The bale shape indicator arrows are also accompanied by a series of beeps so the operator does not need to watch the screen. A low tone is emitted when the operator needs to steer left and a higher tone for when the operator needs to steer right.

McHale machines work in different conditions around the world. To optimise performance, we offer a number of options in the McHale variable chamber range. We recommend you speak with your local dealer/distributor as regards the best configuration to meet your requirements

Options V8950

| Camless Pick-Up | Optional |

| Chopper Unit | 25 knife – Optional |

| Selectable Knives | 0,12,13,25 -Optional |

| 1000rpm Gearbox | Optional |

| Single Belt | N/A |

| Greasing – Automatic Greasing | Optional |

| ISOBUS Integration | Optional |

| Tyre Options | 560 / 45 / 22.5 |

| Brakes | Hydraulic -Optional

Air- Optional |

Camless Pick-Up

The 2.1m camless pick-up runs smoothly, particularly in short crop, and requires less maintenance due to a reduced number of rotating parts. All camless pick-ups in the McHale variable chamber baler range are fitted with six tine bars and a double crop roller to provide excellent ground cleaning and fast delivery of crop to the rotor.

Rotor / Chopper Unit

The 25 knife rotor and chopper unit is available as an option on the McHale V6750,V8950 and Fusion Vario variable chamber machines and delivers a chop length of approximately 46mm.

Selectable Knives

A selectable knife system consists of two knife banks which allow for various knife configurations to be chosen depending on the knife bank specification. If a machine is equipped with 25 knives, then a bank of 12 and a bank of 13 knives are available to be chosen from. If no chopping is required then the operator can select for no knives to be engaged. On all V8950 machines, knife selection is engaged from the baler. On all Fusion Vario machines, knife selection can be decided from the tractor cab.

1000rpm Gearbox

McHale machines work in different conditions around the world so in order to optimise machine performance, a 1000rpm gearbox is available as an optional upgrade on all machines in the McHale baler range.

Brakes

All balers in the McHale V8 variable chamber baler range can be equipped with brakes as an optional extra. McHale offer the choice of hydraulic or air brakes. All McHale Fusion Vario machines come fitted with hydraulic brakes as standard but can be specified with air brakes as an optional extra.

Single Belt

A single, full width, endless belt exerts a high pressure on the crop in order to form a dense bale in the chamber. Heavy-duty belts are manufactured to the highest of standards using layers of synthetic and rubber material to form a durable endless belt with no joins. This full width belt reduces crop loss, particularly in alfalfa and provides better belt traction for the operator compared to multiple endless belts.

Automatic Greasing

Automatic greasing is available as an option on all McHale V8950 machines. Automatic greasing saves time as it reduces the amount of manual greasing to be done by the operator. All drive and non-drive side chamber bearings and rotor bearings are greased as the machine is working through the automatic greasing cycle. A measured amount of grease is distributed around the machine every time the bale chamber door opens on the McHale V8950. The grease cartridge should be replaced after 1200 bales.

ISOBUS Integration

ISOBUS is available as an optional extra on all McHale V6750 and V8950 machines. When the machine is fitted with ISOBUS, it can be plugged into any ISOBUS tractor connection and operated through the terminal in the cab.

Tyre Options

McHale offer a number of tyre upgrades depending on customer preferences and ground conditions.

Read lessWatch the video for the McHale V8950 semi-automatic variable chamber baler which is fitted with a 15-knife chopper unit and heavy-duty rotor capable of producing bales from 0.6–1.9m (2’–6’3″).

| Length | 5.1m (16’ 9”)* |

| Width | 2.58m / 2.62m

(8’ 6” / 8’ 7”)* |

| Height | 3.12m (10’ 3″) |

| Weight | 4850kg

(10,692 lbs)* |

| * Value will vary depending on specification | |

| Working Width | 2100mm (6’ 11”) |

| Tine Bars | 5 (6 on Camless Pick-up) |

| Tine Spacing | 70 mm |

| Short Crop Guard | Option |

| Crop Roller | Standard |

| Pick Up Guide Wheels (pneumatic) | Standard |

| Number of Knives | 15 |

| Theoretical Chop Length | 65 mm |

| Knife Protection | Hydraulic |

| Knife Deactivation | Hydraulic from Cab |

| Unblocking System | Drop Floor |

| Diameter | 0.6 m (2’) to 1.9 m (6’ 3”) |

| Width | 1.23 m (4’) |

| Bale Chamber Feed | 15 Knife Chopper Feed Rotor |

| Number of Belts | 3 |

| Control | Manual or Automatic |

| Net System | High Performance Netter |

| Net Roll Capacity | 1 + 2 Storage |

| Net Adjustment | In Cab |

| Gearbox | Split Drive |

| Main Drive Protection | Cam Clutch |

| Pick-Up Protection | Slip Clutch |

| Chain Lubrication | Continuous |

| Bale Chamber | Double Drive |

| Control System | Expert Plus |

| Operation | Semi-Automatic |

| Density Adjustment | In Cab |

| Bale Size Adjustment | In Cab |

| Axle | 8 Stud |

| Brakes | Option: Air / Hydraulic |

| Tyres Standard | 500/50/22.5 |

| Tyres Optional | 560/45/22.5 |

| Bale Kicker | Adjustable |

| Road Lights | Standard |

| Minimum Hydraulic Flow | 30 l/min @180 bar |

| Hydraulic System | 2 double acting spools, 1 free flow return |

| Electronics | 12 Volt DC, 20 amp |

| Minimum PTO Requirements | 60 kW (80hp) |