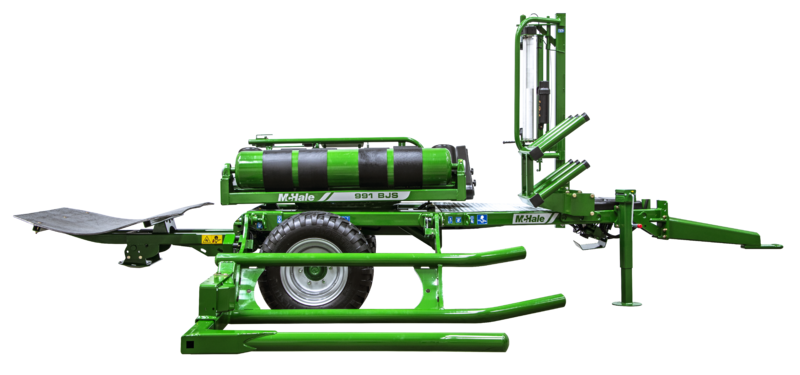

The McHale 991 BE is the top of the range fully automatic, electronic, single dispenser machine in the 991 B Range. The machine features an Auto Load function which automatically loads the bale on the wrapping table. The fully automated Expert electronic control console allows the operator to select from 3 cycle options:

| Automatic Wrapping Cycle (Manual load & tip) | Automatic Load and Wrap Cycle (Manual tip) | Automatic Load – Wrap and Tip Cycle |

| Expert Control Console (Fully automatic cycle) | Auto Load Lift Arm Function | Film Break Sensor |

| Automatic Cut & Hold System | McHale Patented Ground Supported Damper | Capacity to carry 7 rolls of film (6 & 1) |

| 750mm Quick Fit Film Dispenser | Ability to static wrap when using the optional remote control | |

| Transport Length | 5.7 m (18’8″) |

| Transport Width | 2.45 m (8′) |

| Transport Height | 2.46 m (8’1″) |

| Height to Top of Rollers | 1.25 m (4’1″) |

| Weight (unladen) | 1870 kg (4123 lbs) |

| Bale Size | 1.52 m (3’3″-5′) |

| Aluminum Dispensers | 1 x 750 mm

Optional 500 mm Kit |

| Film Stretch | 70% Standard

55% Optional |

| Wrapping Speed (up to) | 30 rotations/min |

| Wrapping System | Turntable |

| Protection Mechanism | Shear Bolt |

| Lift Capacity

@ 170 bar |

1100 kg (2425 lbs) |

| Driver Control | Expert Control Console |

| Operation | Automatic & Manual |

| Radio Remote Control | Optional |

| Film Roll Capacity | X 7 (1+6) |

| Cut & Hold | Yes |

| Bale Wrap Monitor | Yes |

| Road Lights | Yes |

| Greasing Points | 19 |

| Wheel Dimensions | 340/55-16 |

| Axle | 6 Stud |

| Attachment to Tractor | Pin Hitch |

| Min. Hydraulic Requirements | 22 l/min @ 170 bar |

| Hydraulic Connections | 2 x 1/2″ QR’s Open

or Closed Centre |

| Electrical Requirements | 12v EuroPlug, 20A or Direct from Battery |

| Minimum hp Requirement | 35 kW / 47 hp |